AZPB-01-1500

with delivery across Russia

AZPB-01-1500

with delivery across Russia

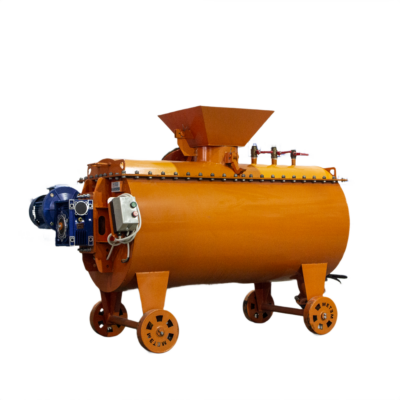

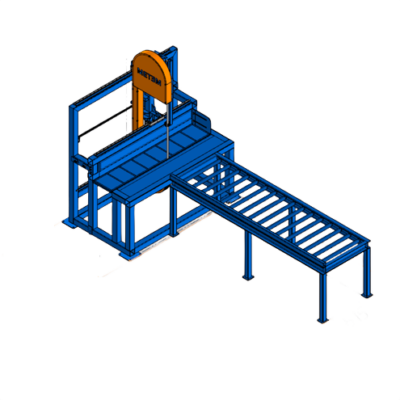

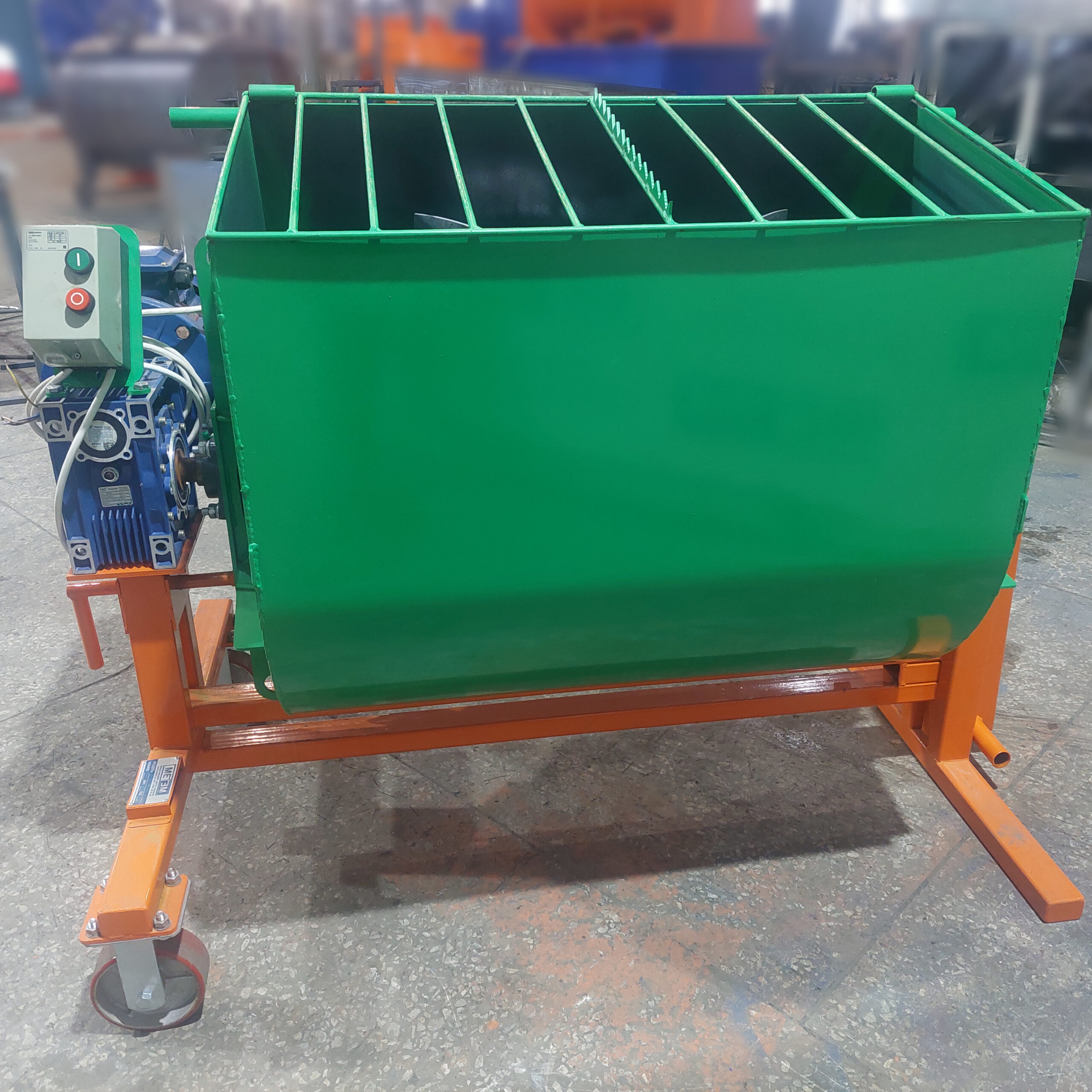

The line "AZPB-01-1500" is designed for the production of polystyrene concrete mixture.

The order of its work*:

1. Water flows by gravity from the storage tank (located directly above the mixer, equipped with an automatic valve D. 90 mm.) into the mixer. The volume of water required for 1 batch is pre-filled into the storage tank using the automatic water dispenser "DZ-V-200". Soft and warm water 25-35 0C is recommended.

2. Next, an air-entraining additive is added to ensure that the polystyrene granules are evenly distributed during mixing.

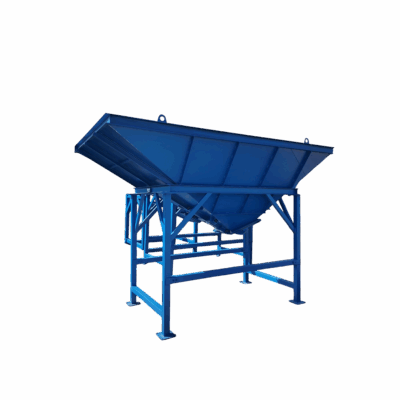

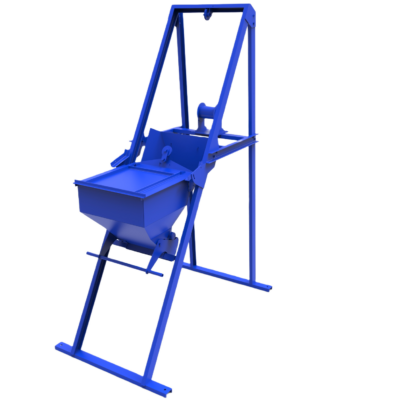

3. Then, using the Volumetric Polystyrene Dispenser, add the foamed polystyrene granules to the mixer. They must first undergo the foaming process. Separately about the foaming process: unfoamed polystyrene granules are poured into the hopper of the Polystyrene Foamer "PP-10", with the help of which the granules are foamed (increased in size up to 50 times) and poured into the receiving funnel of one of the Polystyrene Pneumatic Conveyors "PT-2", which feeds them into the Polystyrene Aging Bunkers "BV-20", where the granules are stabilized (dried out and finished the process of expansion). The recommended time for stabilization is 10-12 hours. It can be reduced by 2 times (to 5-6 hours) if the Polystyrene Dryer "AIST" is installed instead of the Pneumatic Conveyor "PT-2" (see additional equipment). Using the second pneumatic conveyor, the stabilized polystyrene granules are fed into the Volumetric Polystyrene Doser, then see the beginning of point 3.

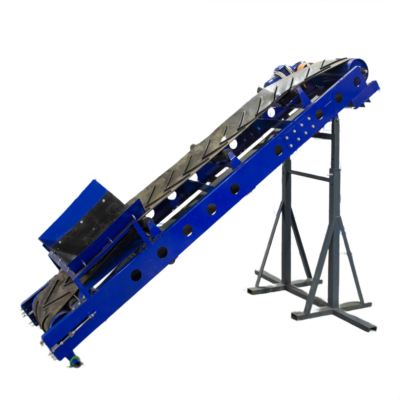

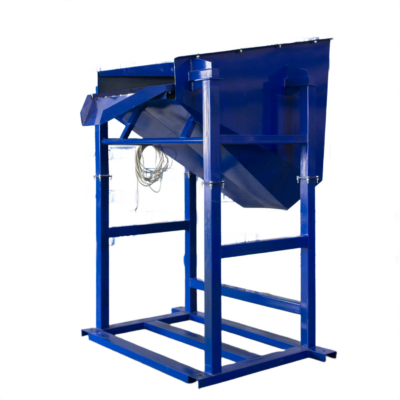

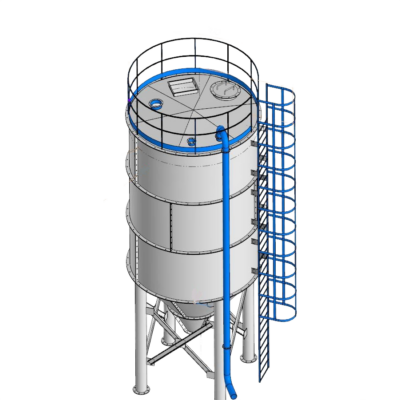

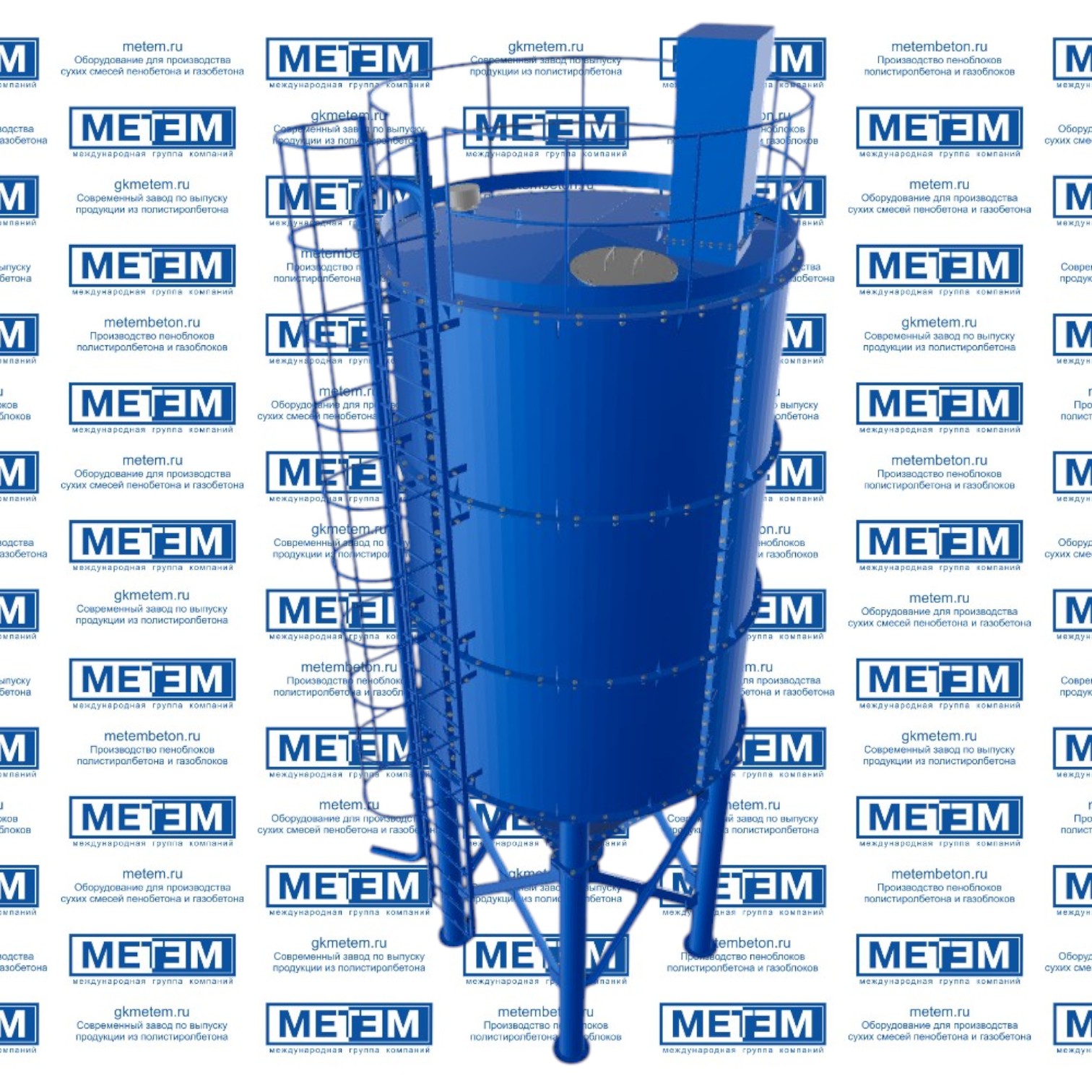

4. Cement is loaded last. The operator sets the required batch weight for 1 batch on the control panel. Then, using the Screw Conveyor "PSh-8000/219", the specified amount of cement is fed from the Big Bag Unloader "RC-01" (to speed up and automate the process, it can be replaced with a Cement Silo, see additional equipment) to the Component Dispenser "DZ-K-01" (equipped with strain gauges for automatic shutdown of the Screw Conveyor and a pneumatic disc valve. After the required amount of cement has been fed to the Dispenser, the operator presses the button, the valve opens and the cement is poured from the Dispenser into the mixer.

5. After all the components have been loaded into the mixer (the mixing element is a spiral), they are mixed into a homogeneous mass. Then the finished polystyrene concrete mixture is unloaded from the mixer into the hopper of the gerotor pump located under the mixer. To do this, the operator needs to press the mixer hatch unloading button located on the control panel. The gerotor pump is then turned on, and the feed is fed into the mold (previously assembled and lubricated) through a rubber sleeve. Then the cycle is repeated until all the necessary molds are filled.

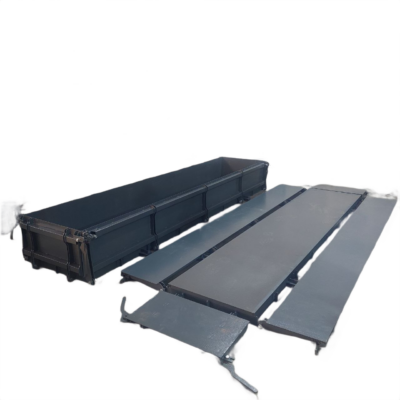

6. We keep polystyrene concrete in the form until the formwork stripping state occurs (from 8 to 24 hours). Polystyrene concrete is dried at positive temperatures, but the recommended temperature is not less than 20 0C and at high air humidity. After the polystyrene concrete has gained the formwork stripping strength, the forms are carefully disassembled and cleaned, and the blocks are placed on pallets, wrapped with stretch film and taken to the warehouse.

*This order of work is not mandatory and indisputable. For example, polystyrene can be loaded last, after cement.

The AZPB-01-1500 line is an effective solution for organizations engaged in the production of polystyrene concrete. It combines the simplicity of the technological process, the reliability of the equipment and the high quality of the final product, ensuring the competitiveness of the enterprise in the construction industry market, without large capital investments in equipment and a production workshop. And taking into account the automatic supply of components, there is also a saving on the number of personnel. When purchasing equipment, GC METEM transfers the technological regulations for the production of polystyrene concrete and a 3D model linked to your building. We guarantee the support of experienced technologists and the possibility of on-the-job training.

Due to the versatility of polystyrene concrete, it can be used to make various small-sized blocks, including tongue-and-groove "lego blocks", large-sized "mega blocks", as well as wall panels, lintels, floor panels, etc.

For work it is also recommended:

- Loader and/or overhead crane.

- Film for creating a greenhouse effect for drying polystyrene concrete mixture.

- Film for creating a greenhouse effect and packaging finished products.

-Wooden pallets for easy transportation of finished products.

No video