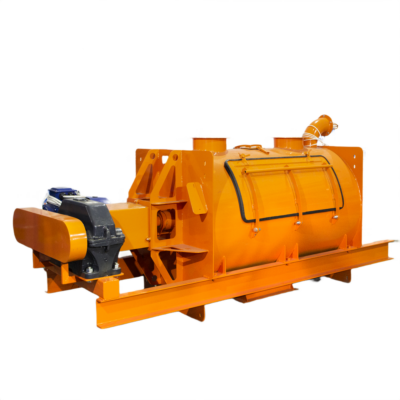

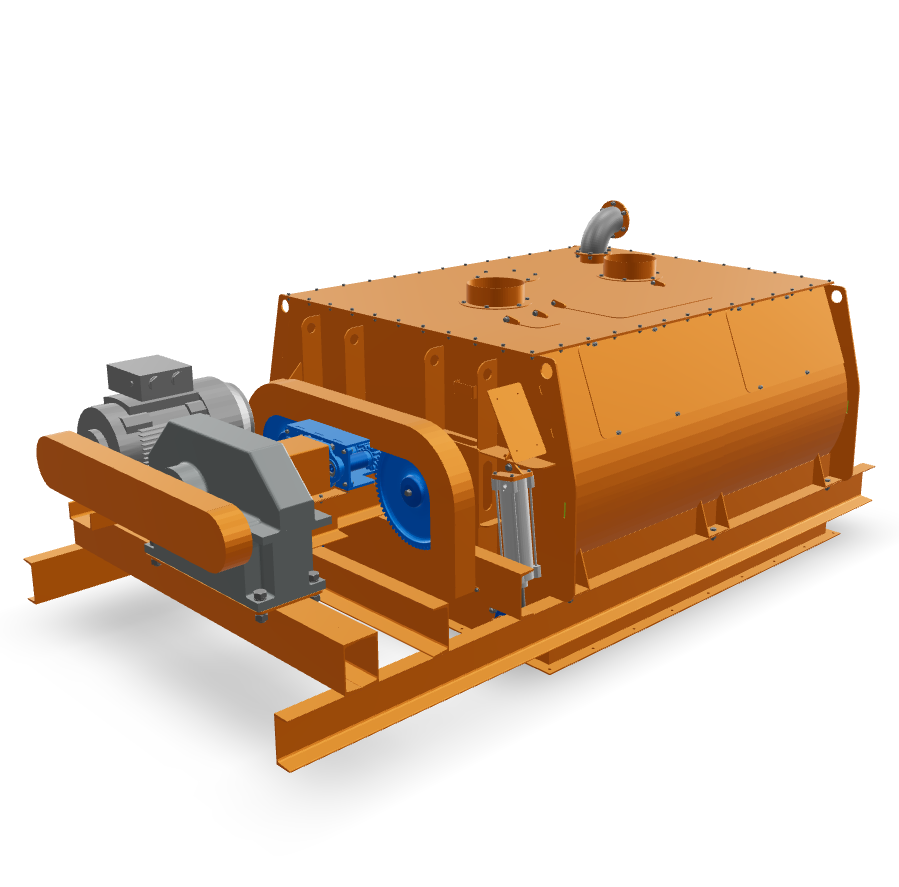

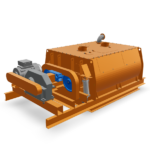

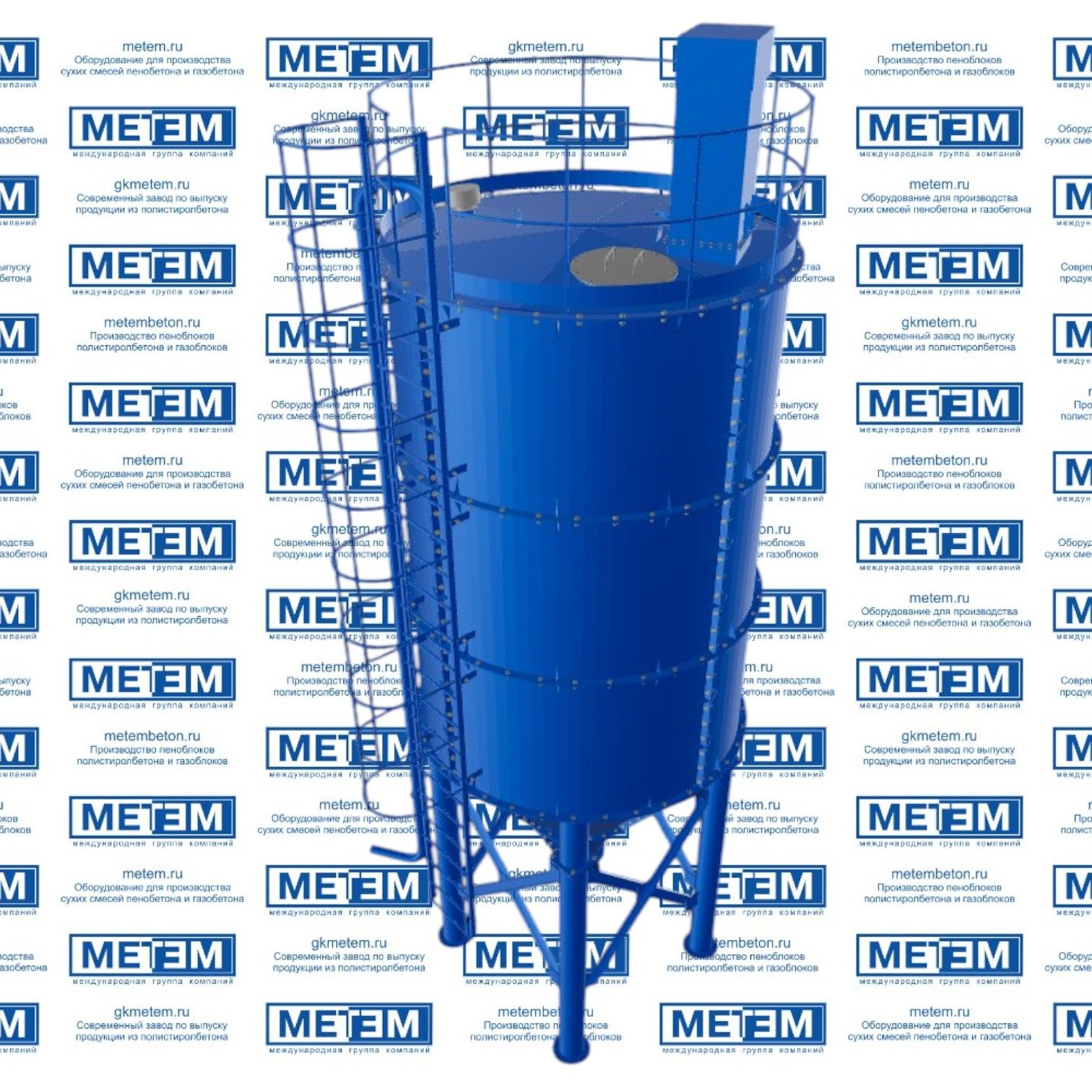

Mixer for dry mixes CC-3000/2

with delivery across Russia

Mixer for dry mixes CC-3000/2

with delivery across Russia

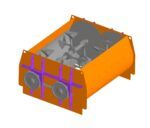

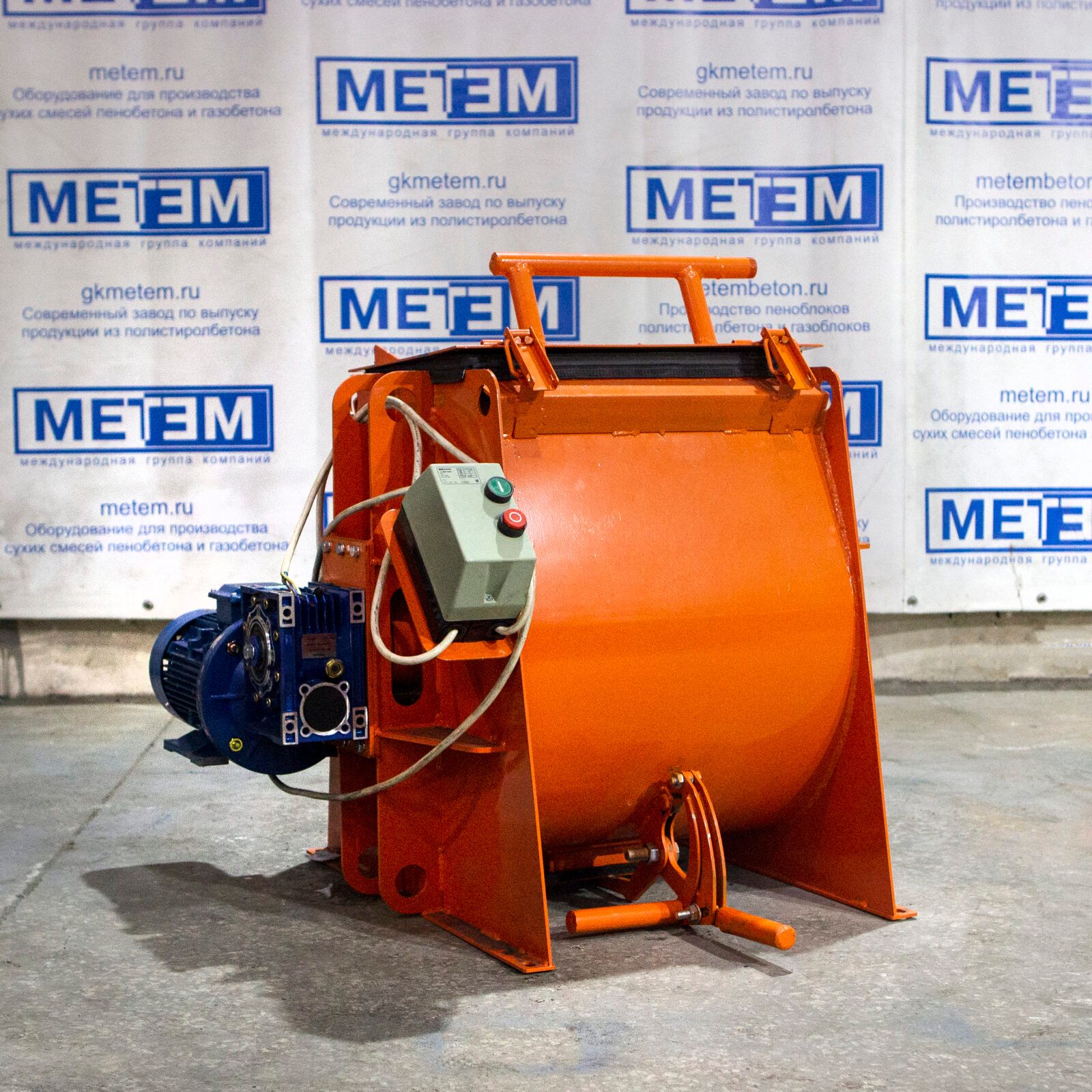

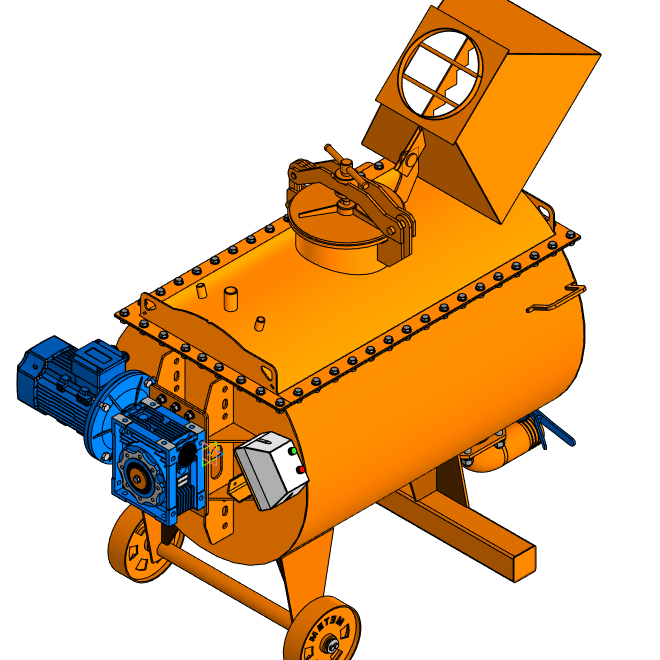

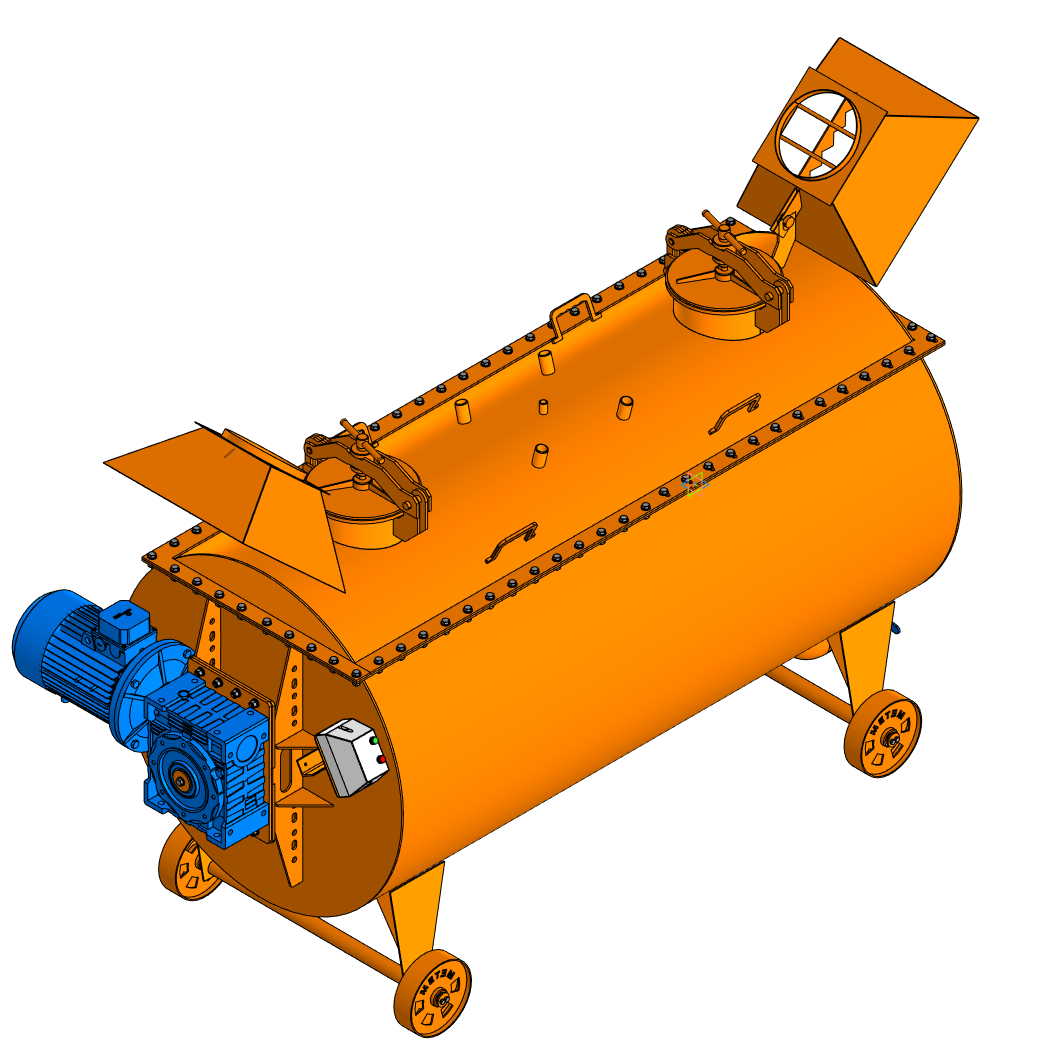

The two-shaft dry mix mixer "SS-3000/2" is designed for mixing bulk materials such as: sand, cement, gypsum, chalk, bentonite, thermoplastic, etc.

Available on back-order

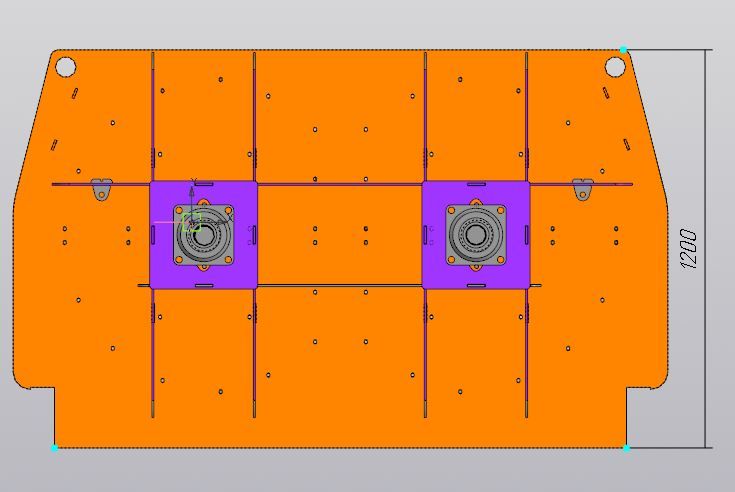

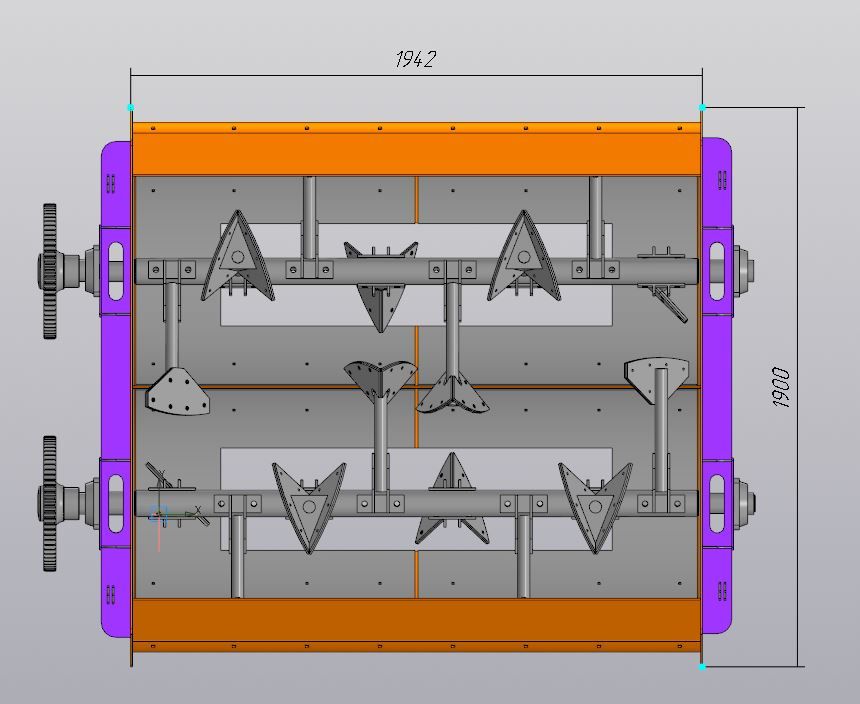

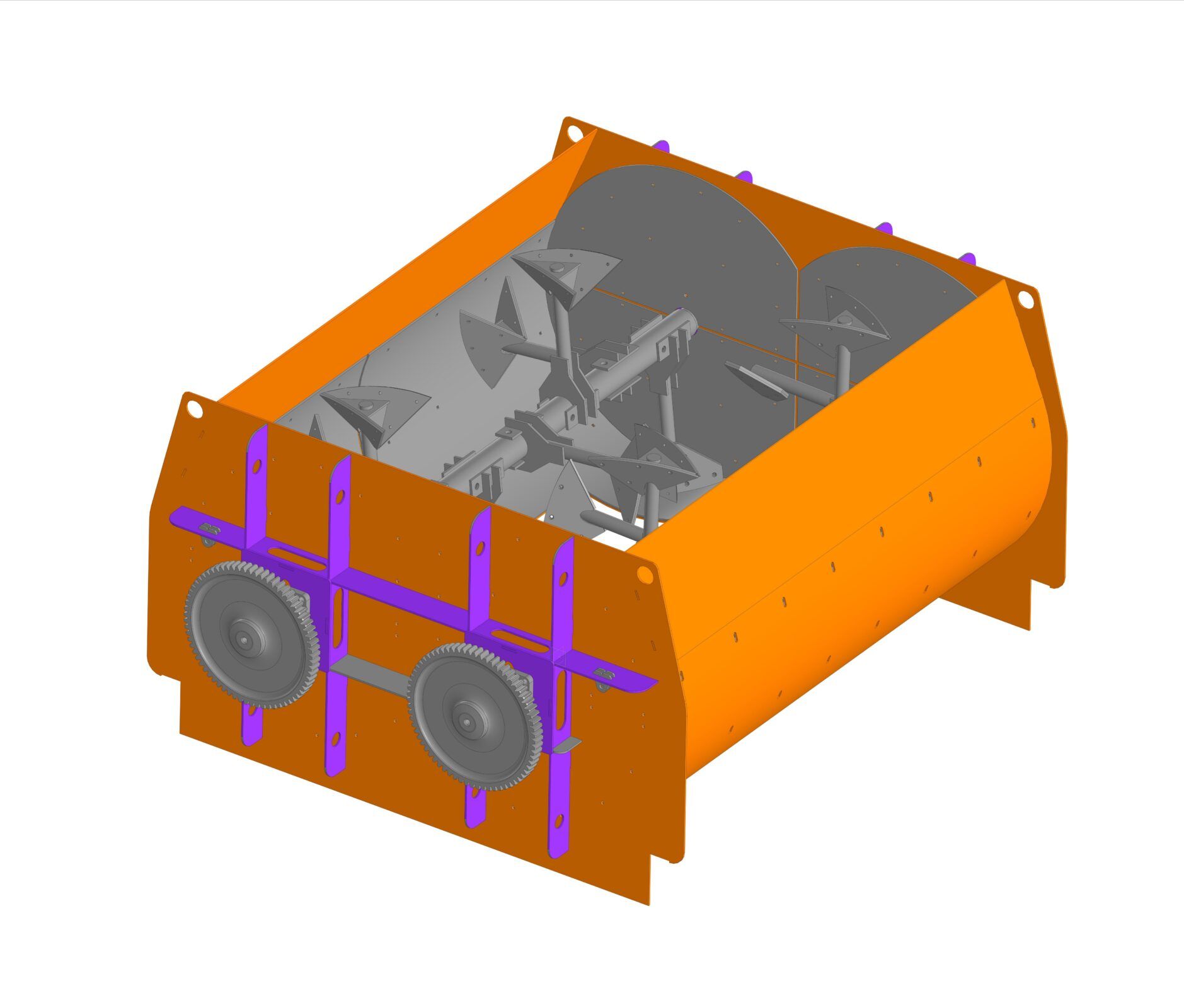

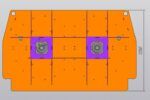

The two-shaft dry mix mixer "SS-3000/2" is designed to mix bulk materials such as: sand, cement, gypsum, chalk, bentonite, thermoplastic, etc. The mixer is equipped with solid metal shafts and reinforced plow blades (other mixing elements can be installed upon request) for fast and high-quality mixing of components. In the lower part, there are unloading hatches with a pneumatic drive for easy unloading of the finished mixture. The hatches are rounded to match the bottom radius, which eliminates the non-mixing zone. The mixer shell is made of 6 mm thick steel, the side walls are 8 mm thick. It is additionally equipped with removable armor. On the "SS-3000/2" shell, inspection hatches are installed on both sides for ease of maintenance, and there are small and large hatches on top for adding additives. The drive has a power of 37 kW. equipped with a cylindrical gearbox and a belt-gear transmission, which simplifies maintenance, reduces noise levels at the production site and increases the service life of the mixer. The upper part is manufactured in agreement with the Customer. Options for manual loading or for any type of conveyors or dispensers are possible.

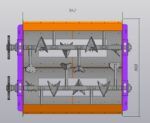

| Weight | 3050 kg |

|---|---|

| Dimensions | 3900×2000×1500 mm |

| Mixer volume |

500 ,l |

| Shaft rotation frequency |

30 ,rpm |

| Performance |

4-5 ,m3/hour |

| Filler fraction |

no more than 5 ,mm |

| Power supply voltage |

380 ,IN |

| Mixer motor power |

7,5 ,kW |

No video

Subscription options

Subscription to "Metem" - everything for the effective start and development of your construction business

By subscribing, you will receive:

✅ Access to dozens of ready-made house projects

An exclusive library of contemporary projects: thoughtful layouts adapted for construction using polystyrene concrete, with an emphasis on energy efficiency and comfort.

✅ Ongoing support from our technologist

Our specialists are always ready to help: consultations on the selection of materials, equipment setup and operation, issues of production technology and pouring of polystyrene concrete.

✅ Free advertising in your region

We recommend your company to our clients in your region - this is an opportunity to attract new customers and increase the recognition of your business. You will also be placed on our website.

✅ Simplified learning of Metem equipment

You'll be able to use our equipment efficiently and effectively faster with access to professional instructions and expert support.

✅ Practical training at the plant in Novye Lyady

A unique opportunity to undergo training at an operating production facility and master Metem technologies in practice - from working with raw materials to finished products.

💼 With a Metem subscription, you save time, receive professional support and attract new clients - everything for a successful start and confident growth!

Open a Metem representative office in your region for the production of polystyrene concrete products with a profitability of 1,000,000 rubles

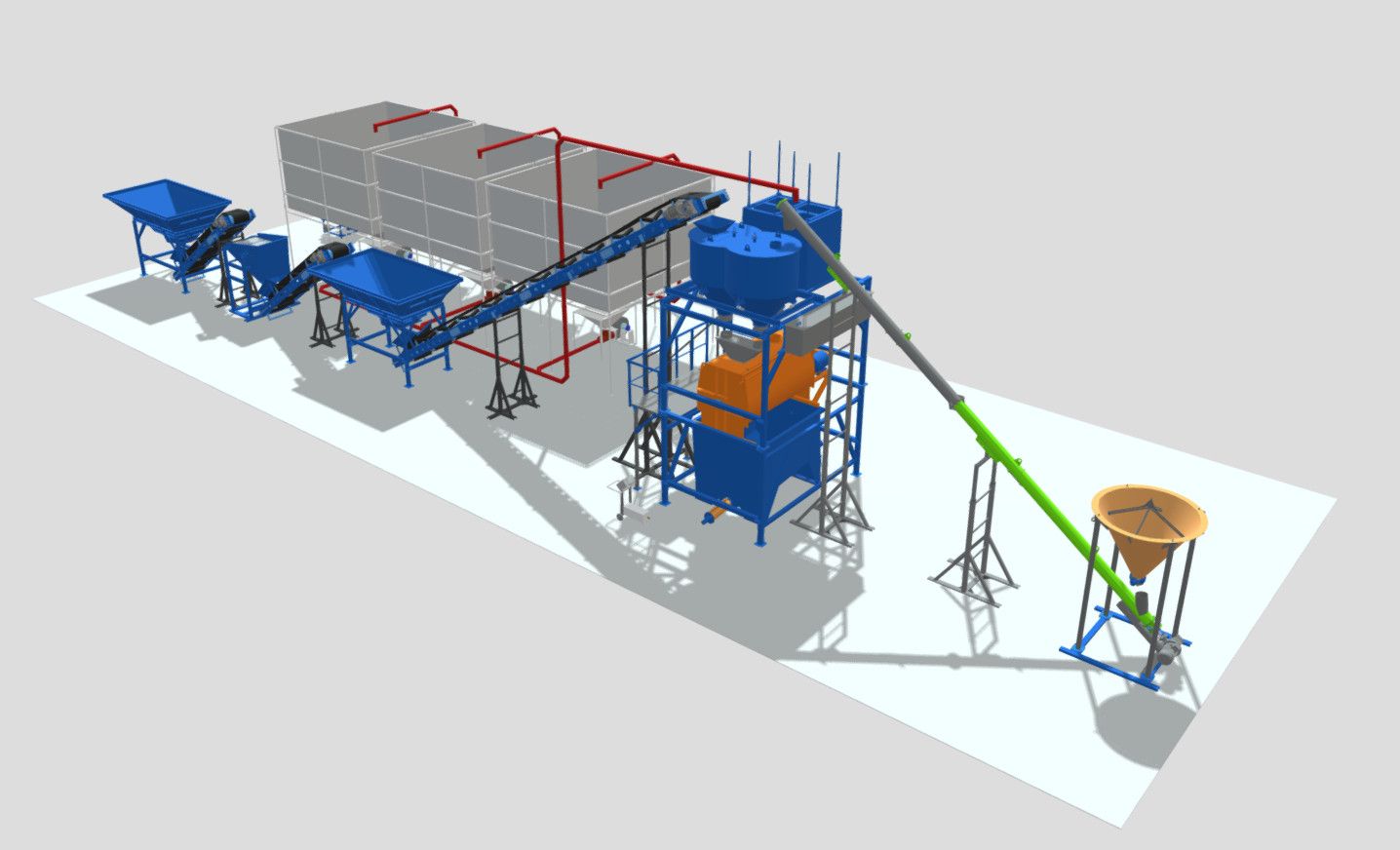

We design, manufacture and launch turnkey projects production lines and plants polystyrene concrete blocks.