Complex for the production of dry mixes "Minimix Compact - 350"

with delivery across Russia

Complex for the production of dry mixes "Minimix Compact - 350"

with delivery across Russia

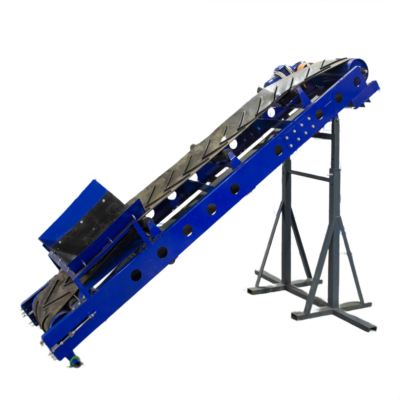

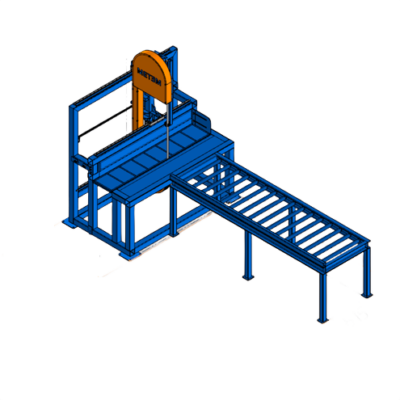

The complex for the production of dry mixes "Minimix Compact - 350" is designed for mixing and packaging bulk mixes in valve and/or open bags.

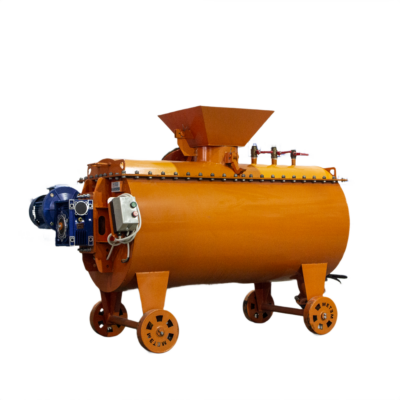

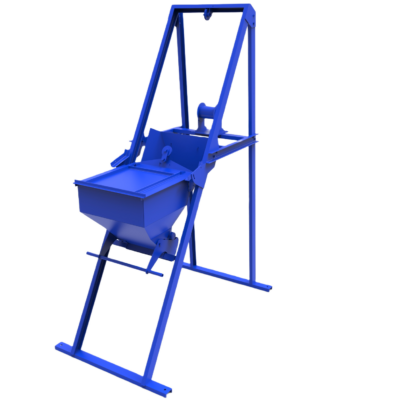

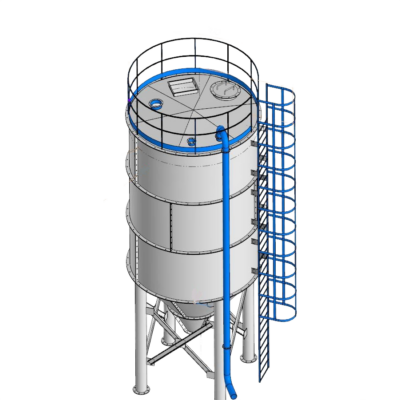

The Minimix Compact 350 dry mix production complex is designed for mixing and packing bulk mixes into valve and/or open bags. Its capacity is up to 1.5 tons per hour. For mixing the components, the complex is equipped with a 350-liter mixer with a reinforced (cylindrical) gearbox, the mixing device in which is a plough blade. Depending on the Customer's tasks, any other blades are possible. For example, flat blades (with or without holes), a spiral, etc. The basic configuration of the mixer is equipped with a manual unloading hatch, it can be replaced with an automatic hatch equipped with a pneumatic cylinder (in this case, a compressor of at least 8 atm. is required), opening and closing with a button.

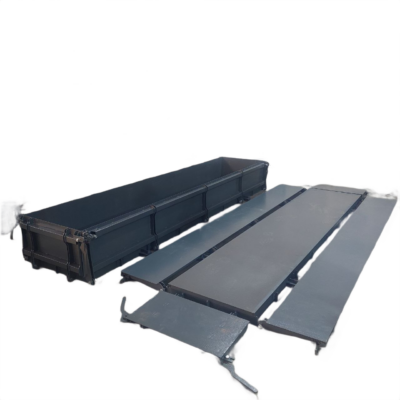

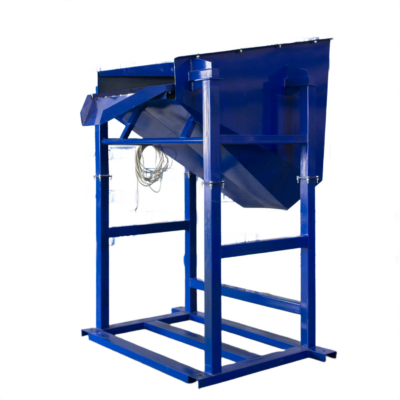

There is an intermediate bin under the mixer, also with a capacity of 350 l. The finished mixture from the mixer is poured into it for further packing into bags. After unloading the finished mixture into the intermediate bin, the worker can immediately pour the components into the mixer and make the next batch, while another worker will be packing into bags.

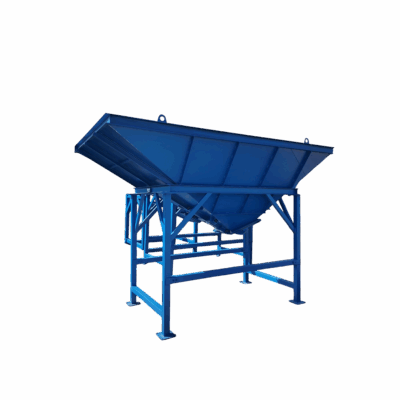

Next, an automatic packing unit is attached to the intermediate bunker (at the bottom), with the help of which the finished mixture in the bunker is packed by the worker into bags. Depending on the Customer's tasks, the option of the packing unit is selected.

Possible options for packaging units:

-Auger packing unit for valve bags.

-Rotary filling unit for valve bags.

-Auger packing unit for open bags.

The finished products, packaged in bags, are placed on a pallet and sent to the warehouse. This principle allows for a continuous packaging process, which allows for maximum productivity in a minimum area.

No video