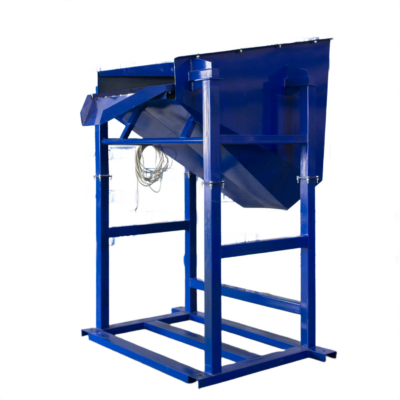

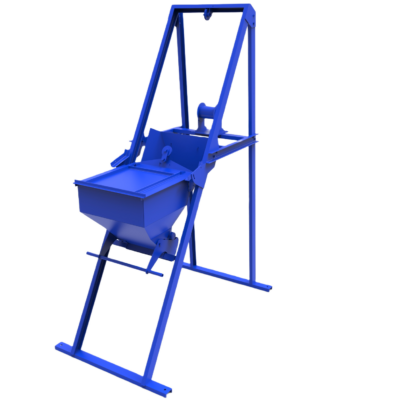

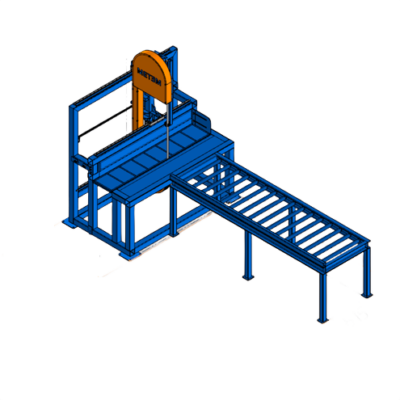

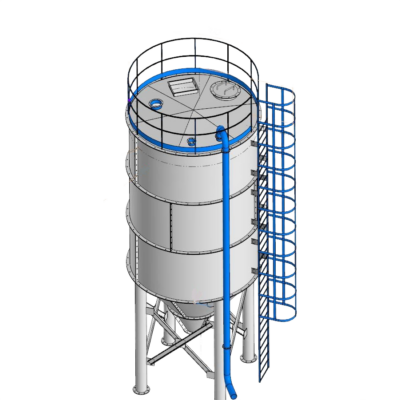

Line for the production of dry building mixtures "Minimix-200"

with delivery across Russia

Line for the production of dry building mixtures "Minimix-200"

with delivery across Russia

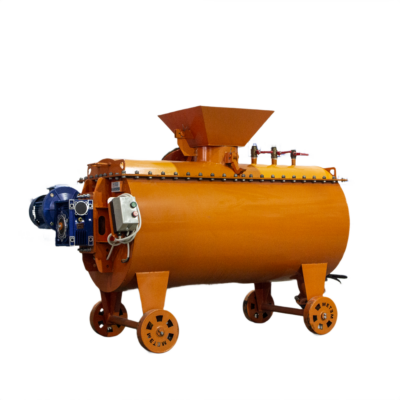

The automated line for the production of dry mixes was developed by the design department of the METEM company. Its capacity is up to 1 ton per hour. The line is equipped with an automatic dosing terminal for precise dosing of components. The mixer has a discharge hatch with a pneumatic drive to reduce the time of unloading the finished mixture. The mixer shell is made of 4 mm thick steel, the side walls are 6 mm. Mixing is done with the help of reinforced blades. The drive is equipped with a cylindrical gearbox, which simplifies equipment maintenance during operation and reduces the noise level at the production site. The line software allows maintaining the optimal operating speed. The control system is set a number of parameters.

To service an automated line, highly qualified personnel are required, at least one operator monitoring the line and one worker transporting raw materials and finished products. A specialist in repairing and setting up such lines is also required, but this position can be combined with the operator's work.

No video

- The production period of the line is 20 working days.

- Payment terms: prepayment 70%, the remaining 30% Buyer pays after the production of the line before shipment

- The Supplier prepares a project for the equipment layout specifically for the Buyer's premises.

- Warranty service 1 year

- The cost of installation, commissioning of the line and training of the Buyer's personnel is calculated individually

- The equipment is delivered to the address by the Buyer. At the Buyer's request, the Supplier may provide equipment delivery services at the Buyer's expense.