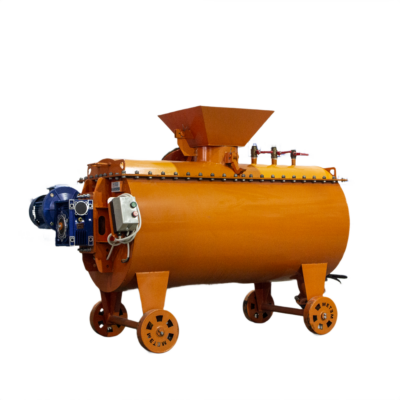

Packing machine "MF-PA-ROTOR"

with delivery across Russia

Packing machine "MF-PA-ROTOR"

with delivery across Russia

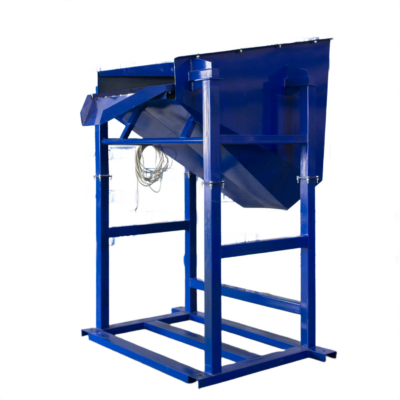

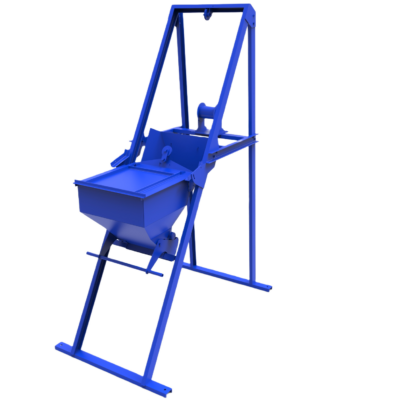

The packing machine "MF-PA-ROTOR" is designed for packing bulk materials (cement, gypsum, alabaster, chalk, etc.) into consumer packaging - valve bags according to GOST 2226.

Available on back-order

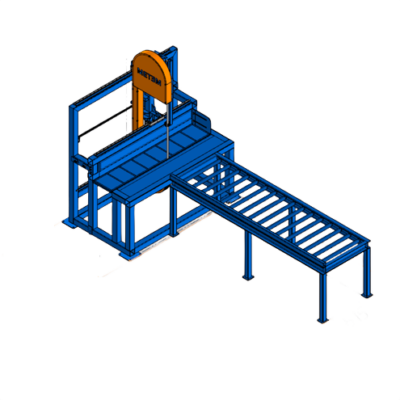

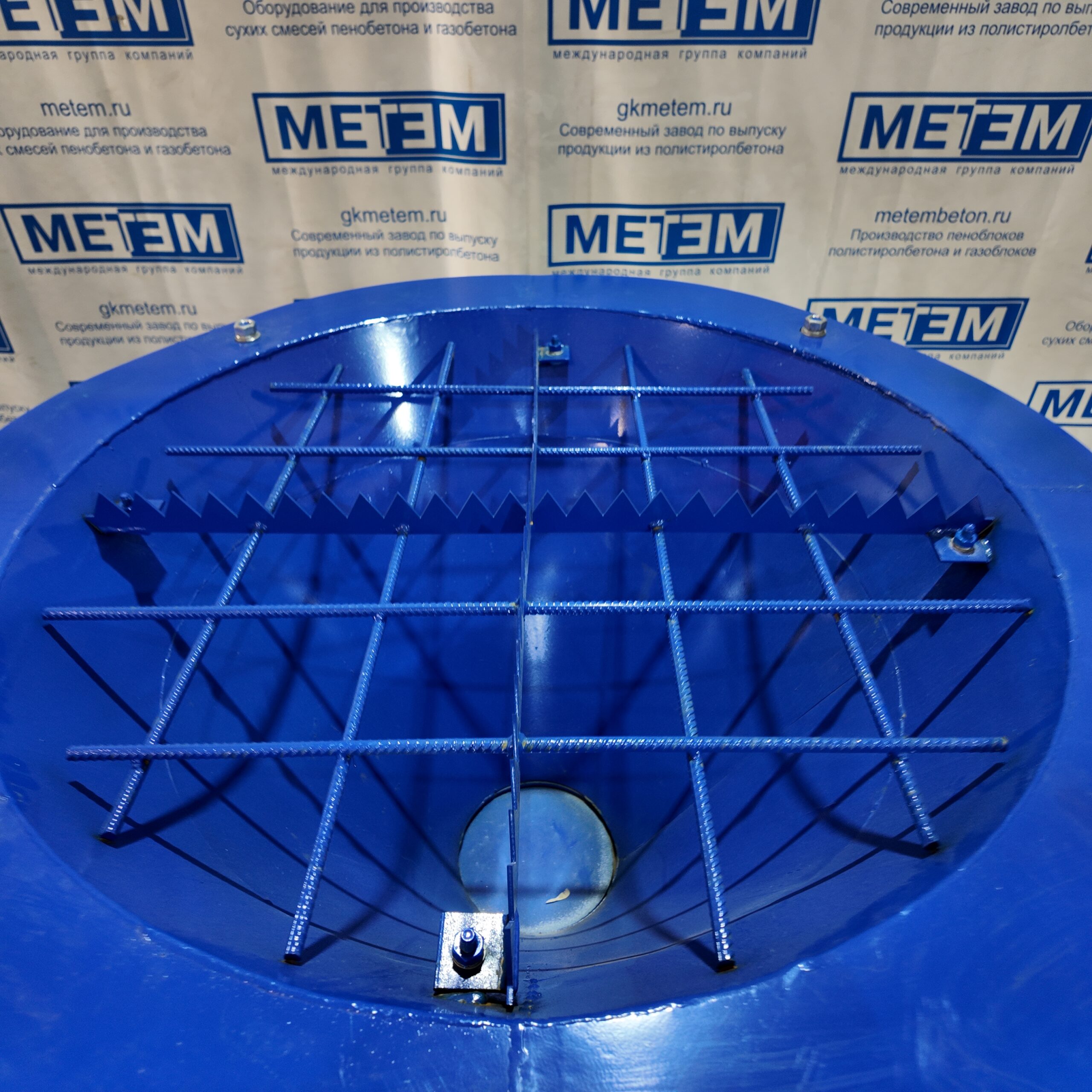

The MF-PA-ROTOR filling machine is designed for filling bulk materials (cement, gypsum, alabaster, chalk, etc.) into consumer packaging – valve bags according to GOST 2226. The unit is a dispenser with an automatic, electromechanical system for dosing bulk materials into valve bags of different sizes (with the same valve). The operator sets the required dose weight on the control panel, puts the bag on the loading nozzle and mechanically clamps (base) the bag. After pressing the START button located on the control panel, the filling process starts. Filling stops automatically when the required dose in the bag is reached. After that, the operator releases the bag from the clamp and removes the bag from the spout. The product is filled into the container using a turbine and a compressor connected to it (not included in the price). The weight is measured using a strain gauge (located on the spout), the signal from which comes to the control unit. For precise dosing, the machine is equipped with a frequency converter. The standard size of the loading spout is 63 mm. (valve 11), it can be changed depending on the Customer's tasks. "MF-PA-ROTOR" should be installed in a room equipped with power wiring, a distribution board, a protective grounding circuit, a ventilation system, and a level floor.

| Weight | 220 kg |

|---|---|

| Dimensions | 1500 × 1000 × 1500 mm |

| Performance |

up to 200 ,kg/min |

| Weight of material in a bag |

up to 50 ,kg |

| Power supply voltage |

380 ,IN. |

| Engine power |

5,5 ,kW. |

| Nominal air pressure |

8 ,atm. |

| Dosing error |

100-300 ,G. |

| Outer diameter of loading nozzle (standard) |

63 ,mm. |