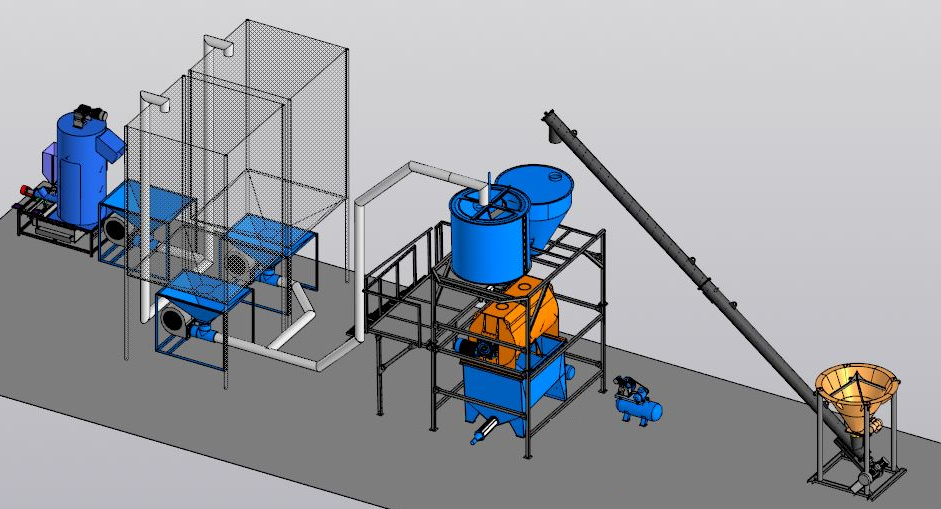

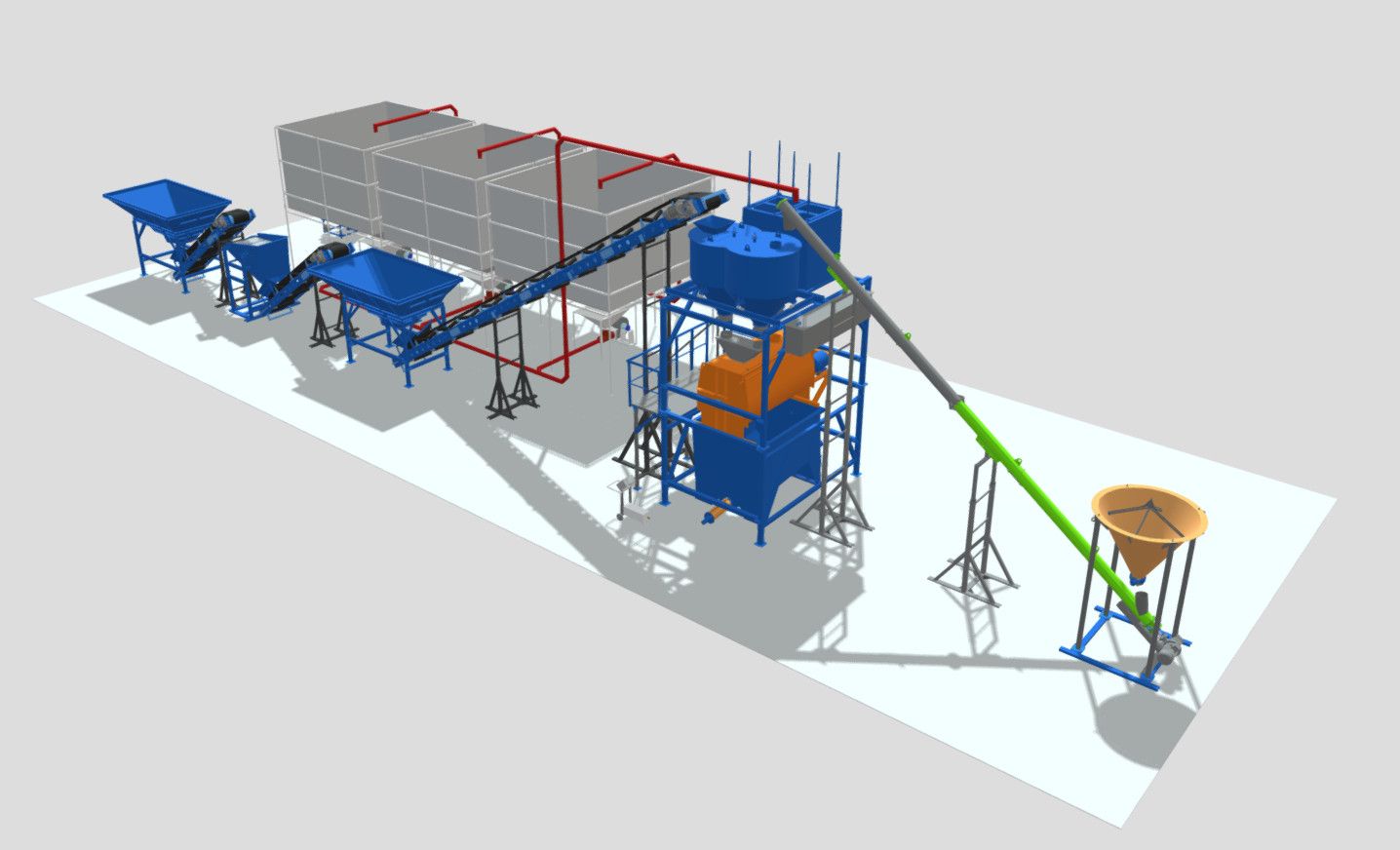

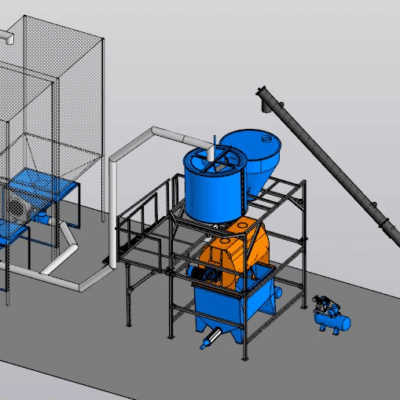

Polystyrene concrete production line AZPB-01-1000

with delivery across Russia

Polystyrene concrete production line AZPB-01-1000

with delivery across Russia

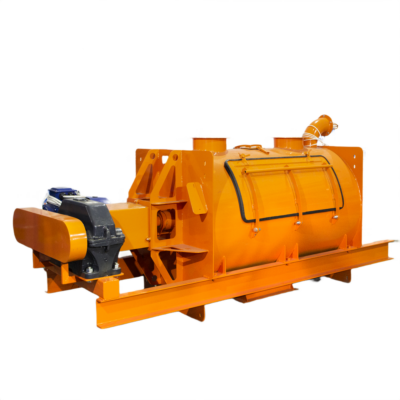

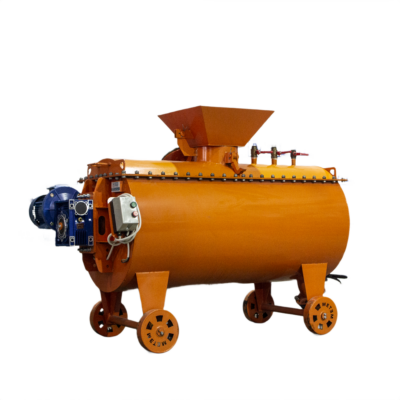

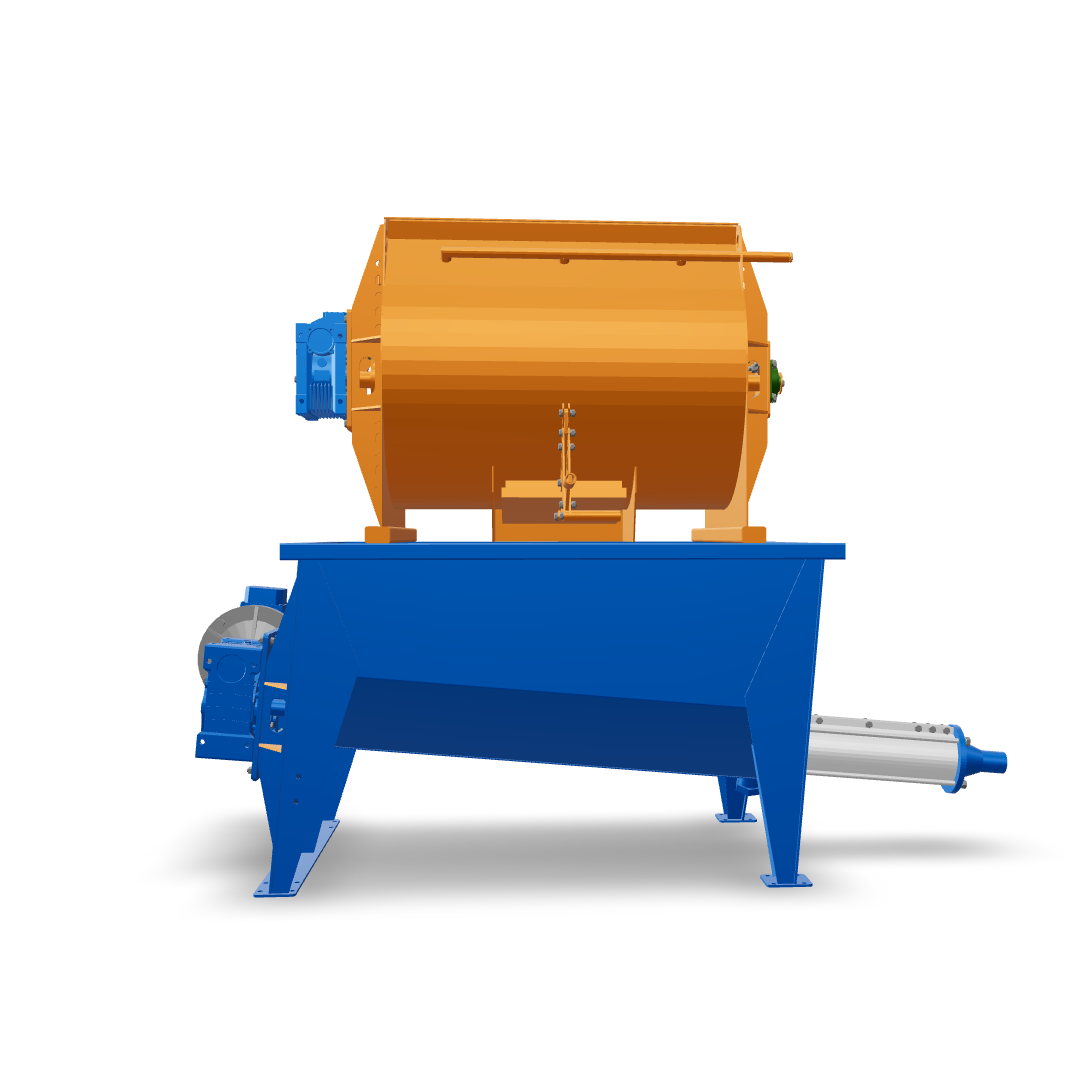

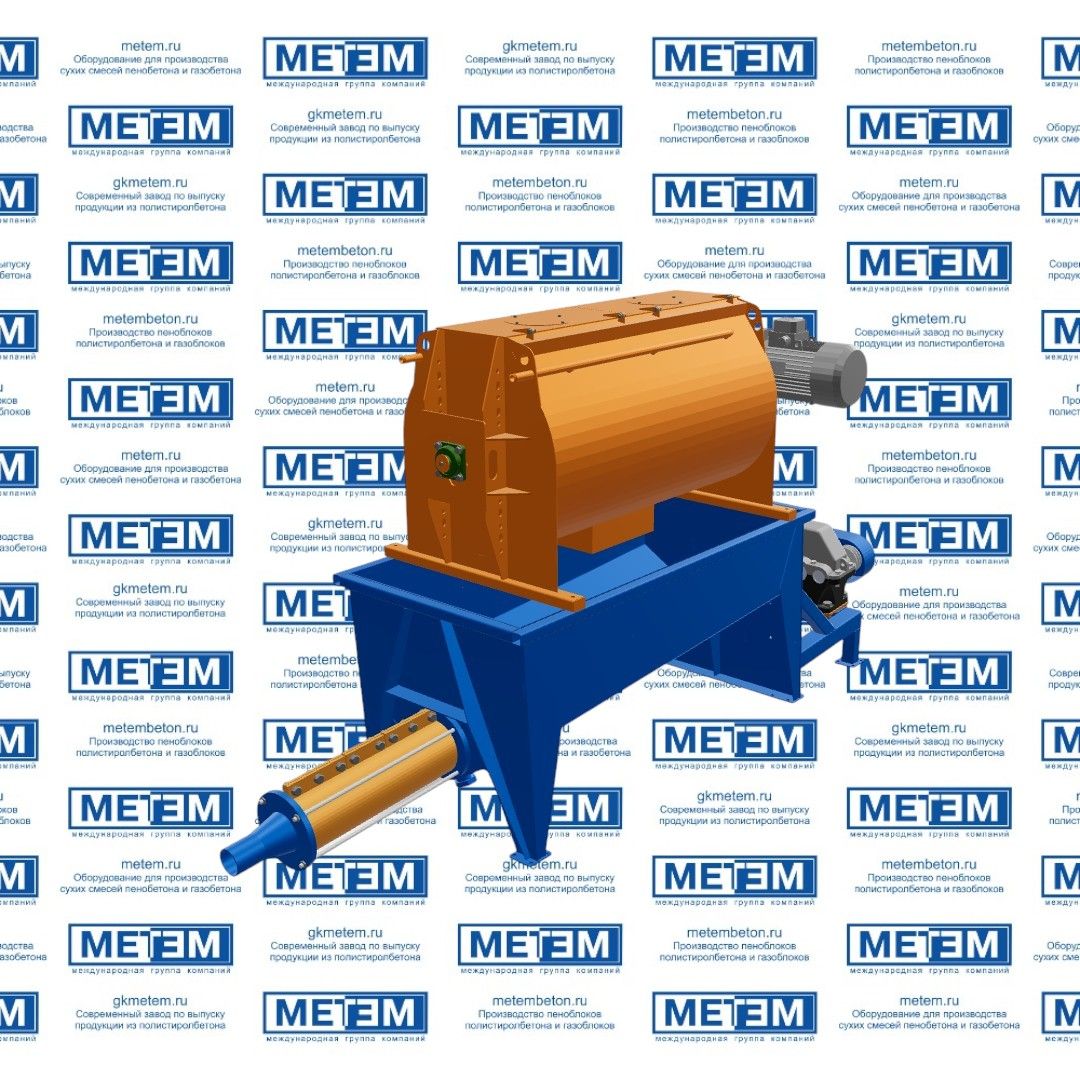

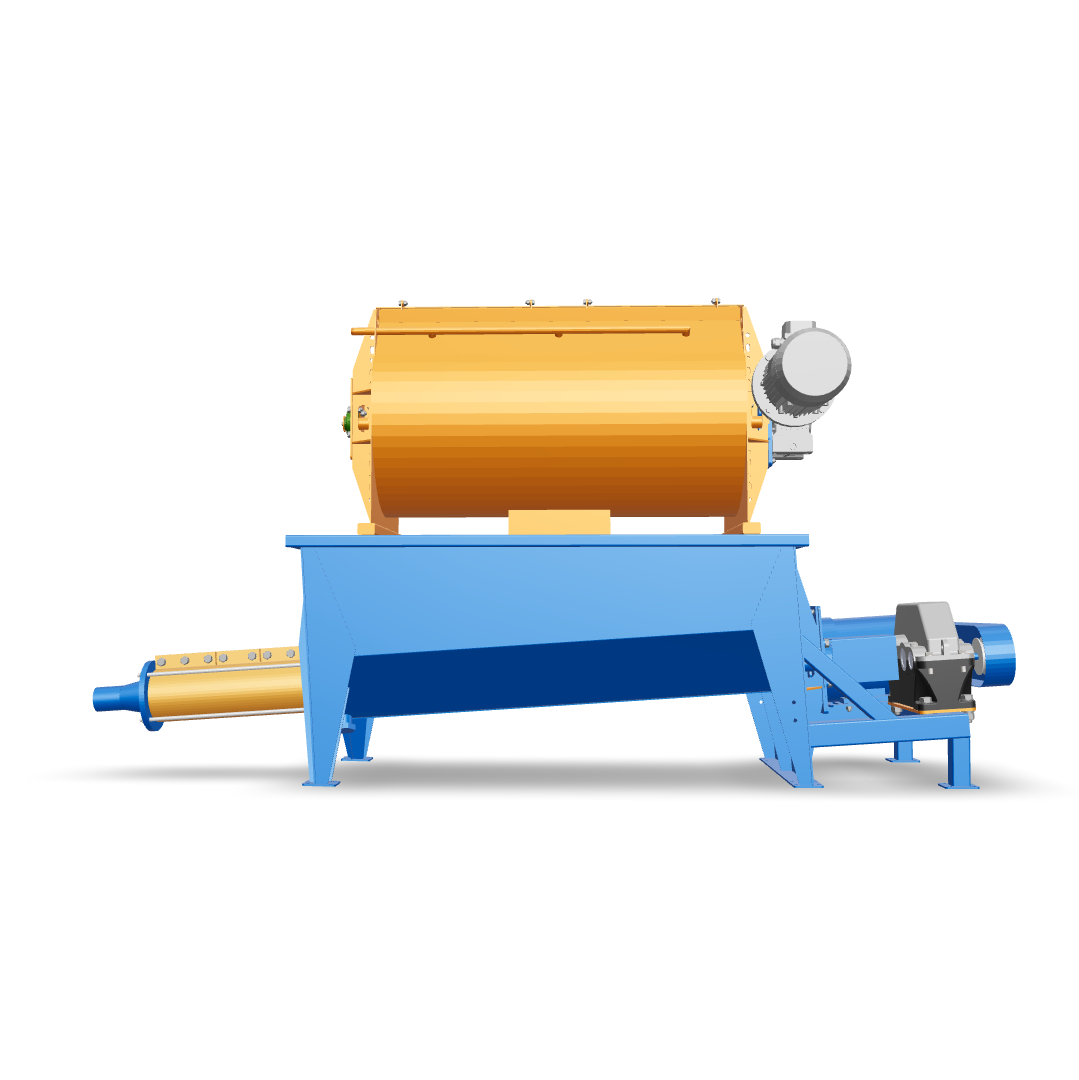

The line "AZPB-01-1000" is designed for the production of polystyrene concrete mixture.

Available on back-order

The order of its work*:

1. Water flows by gravity from the storage tank (located directly above the mixer, equipped with an automatic valve D. 90 mm.) into the mixer. The volume of water required for 1 batch is pre-filled into the storage tank using the automatic water dispenser "DZ-V-200". Soft and warm water 25-35 0C is recommended.

2. Next, an air-entraining additive is added to ensure that the polystyrene granules are evenly distributed during mixing.

3. Затем при помощи Объемного дозатора полистирола добавляем в смеситель вспененные гранулы полистирола. Предварительно они должны пройти технологический процесс вспенивания. Отдельно о процессе вспенивания: невспененные гранулы полистирола засыпаются в бункер Вспенивателя полистирола «ПП-10», при помощи которого гранулы вспениваются (увеличиваются в размере до 50 раз) и высыпаются в приемную воронку одного из Пневмотранспортеров полистирола «ПТ-2», который подает их в Бункера вылеживания полистирола «БВ-20», где гранулы стабилизируются (высыхают и заканчивают процесс увеличения). Рекомендуемое время для стабилизации 10-12 часов. Его можно сократить в 2 раза (до 5-6 часов), если вместо Пневмотранспортера «ПТ-2» установить Сушку полистирола «АИСТ» (см. дополнительное оборудование). С помощью второго пневмотранспортера стабилизированные гранулы полистирола подаются в Объемный дозатор полистирола, далее см. начало п. 3.

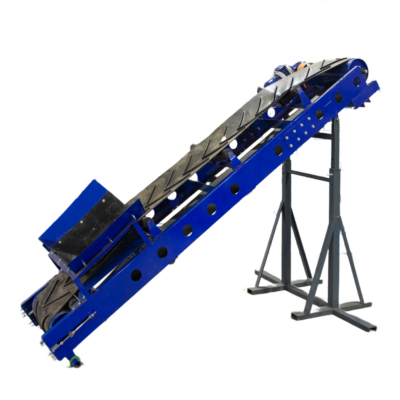

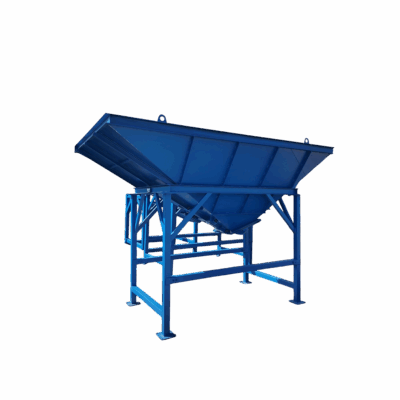

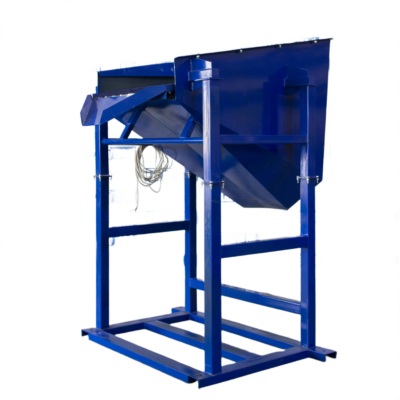

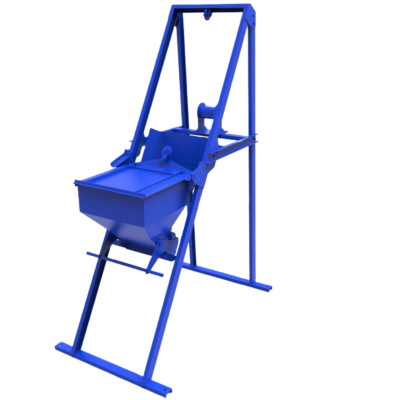

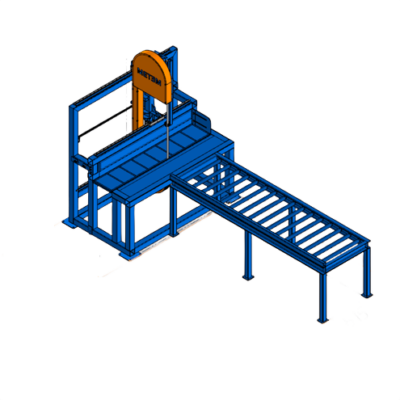

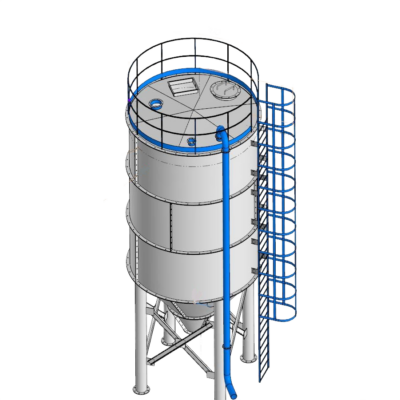

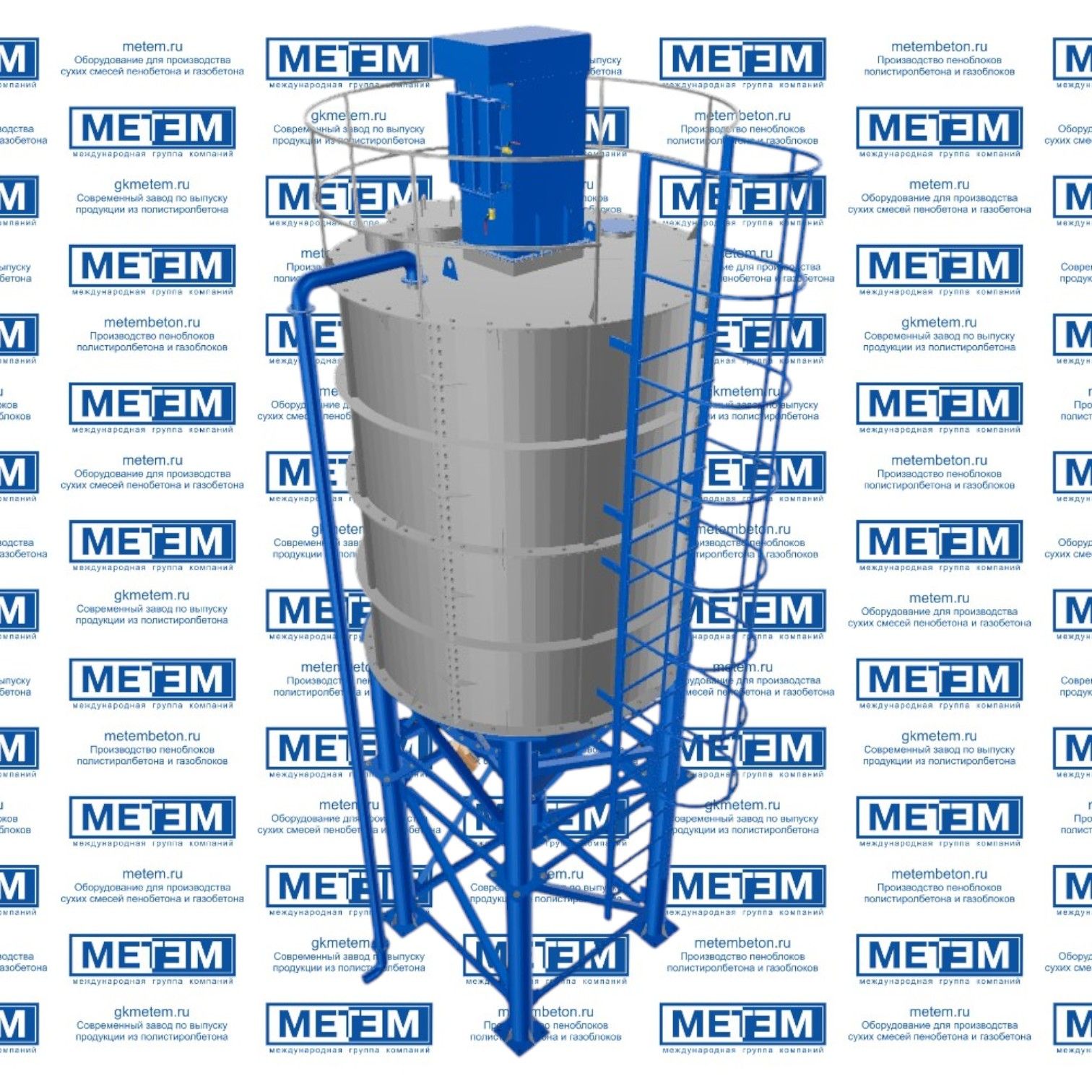

4. Cement is loaded last. The operator sets the required batch weight for 1 batch on the control panel. Then, using the Screw Conveyor "PSh-8000/219", the specified amount of cement is fed from the Big Bag Unloader "RC-01" (to speed up and automate the process, it can be replaced with a Cement Silo, see additional equipment) to the Component Dispenser "DZ-K-01" (equipped with strain gauges for automatic shutdown of the Screw Conveyor and a pneumatic disc valve. After the required amount of cement has been fed to the Dispenser, the operator presses the button, the valve opens and the cement is poured from the Dispenser into the mixer.

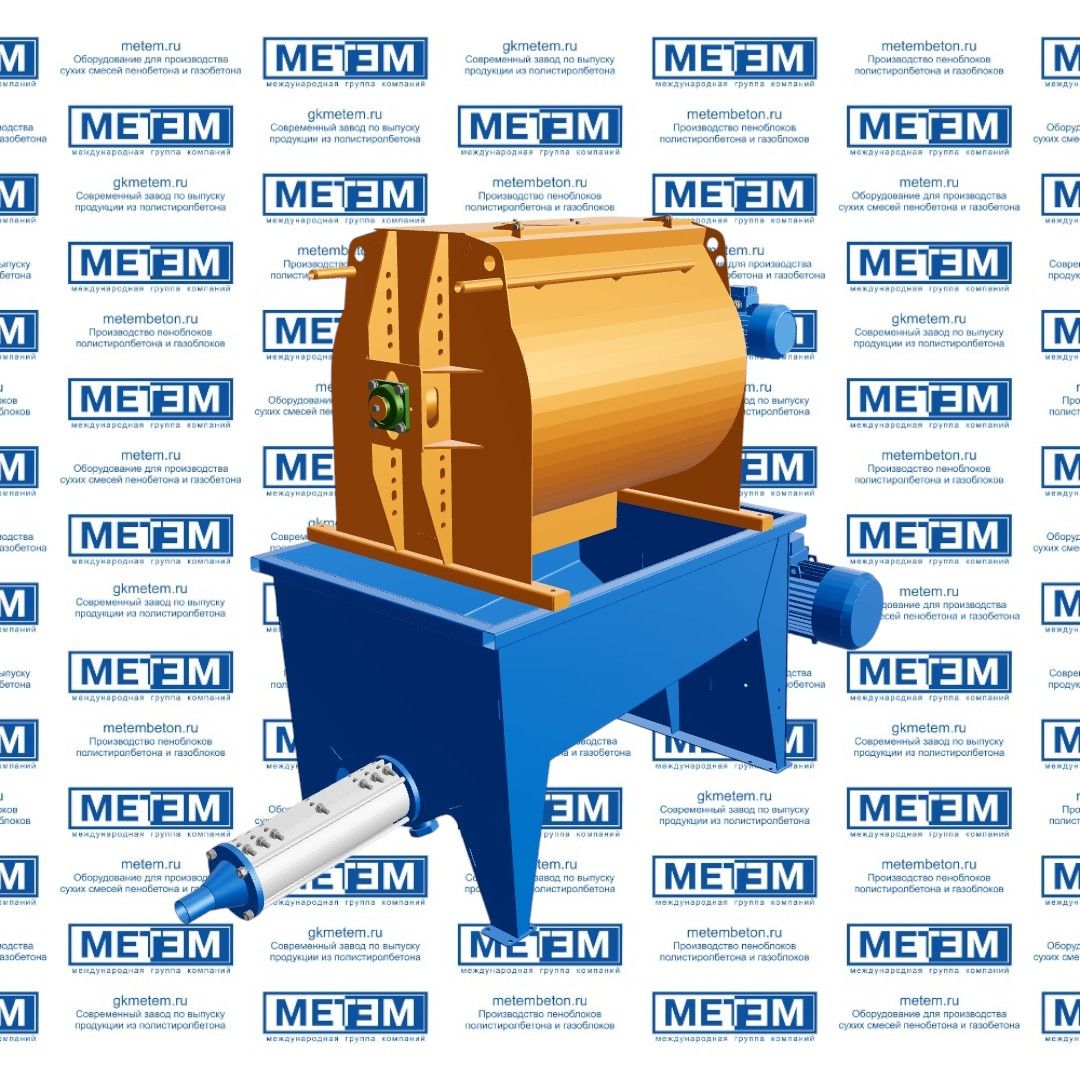

5. After all the components have been loaded into the mixer (the mixing element is a spiral), they are mixed into a homogeneous mass. Then the finished polystyrene concrete mixture is unloaded from the mixer into the hopper of the gerotor pump located under the mixer. To do this, the operator needs to press the mixer hatch unloading button located on the control panel. The gerotor pump is then turned on, and the feed is fed into the mold (previously assembled and lubricated) through a rubber sleeve. Then the cycle is repeated until all the necessary molds are filled.

6. We keep polystyrene concrete in the form until the formwork stripping state occurs (from 8 to 24 hours). Polystyrene concrete is dried at positive temperatures, but the recommended temperature is not less than 20 0C and at high air humidity. After the polystyrene concrete has gained the formwork stripping strength, the forms are carefully disassembled and cleaned, and the blocks are placed on pallets, wrapped with stretch film and taken to the warehouse.

*This order of work is not mandatory and indisputable. For example, polystyrene can be loaded last, after cement.

The AZPB-01-1000 line is an effective solution for organizations engaged in the production of polystyrene concrete. It combines the simplicity of the technological process, the reliability of the equipment and the high quality of the final product, ensuring the competitiveness of the enterprise in the construction industry market, without large capital investments in equipment and a production workshop. And taking into account the automatic supply of components, there is also a saving on the number of personnel. When purchasing equipment, the METEM Group of Companies transfers the technological regulations for the production of polystyrene concrete and a 3D model linked to your building. We guarantee the support of experienced technologists and the possibility of on-the-job training.

Due to the versatility of polystyrene concrete, it can be used to make various small-sized blocks, including tongue-and-groove "lego blocks", large-sized "mega blocks", as well as wall panels, lintels, floor panels, etc.

For work it is also recommended:

- Loader and/or overhead crane.

- Film for creating a greenhouse effect for drying polystyrene concrete mixture.

- Film for creating a greenhouse effect and packaging finished products.

-Wooden pallets for easy transportation of finished products.

| Performance |

до 100 м³/сутки |

|---|---|

| Recommended workshop area |

500-600 м² |

| Высота |

от 5,5 м |

| Nominal power consumption |

82 кВт./час |

| Recommended workshop temperature |

от 20°С |

| Number of staff |

3-4 people |

No video

- Срок изготовления завода 45 рабочих дней

- Условия оплаты:

-70% от стоимости Товара, оплачиваются Покупателем в качестве предоплаты

-30% от стоимости Товара, оплачиваются Покупателем после получения уведомления о готовности товара к отгрузке.

- Гарантийное обслуживание 2 года.

- Ко всему оборудованию прилагаются паспорта, а также технический регламент по изготовлению полистиролбетона

- Доставка оборудования до адреса осуществляется силами Покупателя. По желанию Покупателя и за его счёт, Поставщик может оказать услуги по доставке оборудования

Subscription options

Subscription to "Metem" - everything for the effective start and development of your construction business

By subscribing, you will receive:

✅ Access to dozens of ready-made house projects

An exclusive library of contemporary projects: thoughtful layouts adapted for construction using polystyrene concrete, with an emphasis on energy efficiency and comfort.

✅ Ongoing support from our technologist

Our specialists are always ready to help: consultations on the selection of materials, equipment setup and operation, issues of production technology and pouring of polystyrene concrete.

✅ Free advertising in your region

We recommend your company to our clients in your region - this is an opportunity to attract new customers and increase the recognition of your business. You will also be placed on our website.

✅ Simplified learning of Metem equipment

You'll be able to use our equipment efficiently and effectively faster with access to professional instructions and expert support.

✅ Practical training at the plant in Novye Lyady

A unique opportunity to undergo training at an operating production facility and master Metem technologies in practice - from working with raw materials to finished products.

💼 With a Metem subscription, you save time, receive professional support and attract new clients - everything for a successful start and confident growth!

Open a Metem representative office in your region for the production of polystyrene concrete products with a profitability of 1,000,000 rubles

We design, manufacture and launch turnkey projects production lines and plants polystyrene concrete blocks.