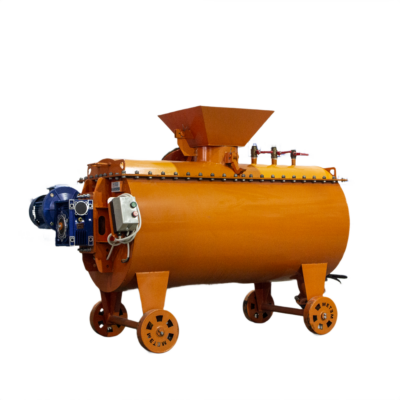

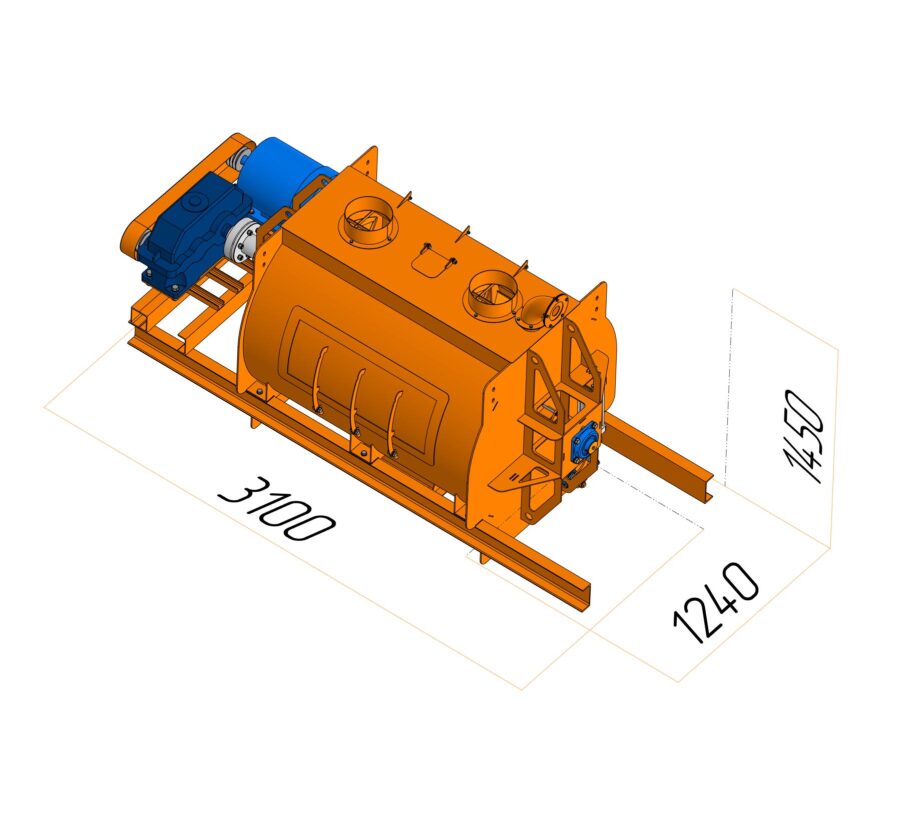

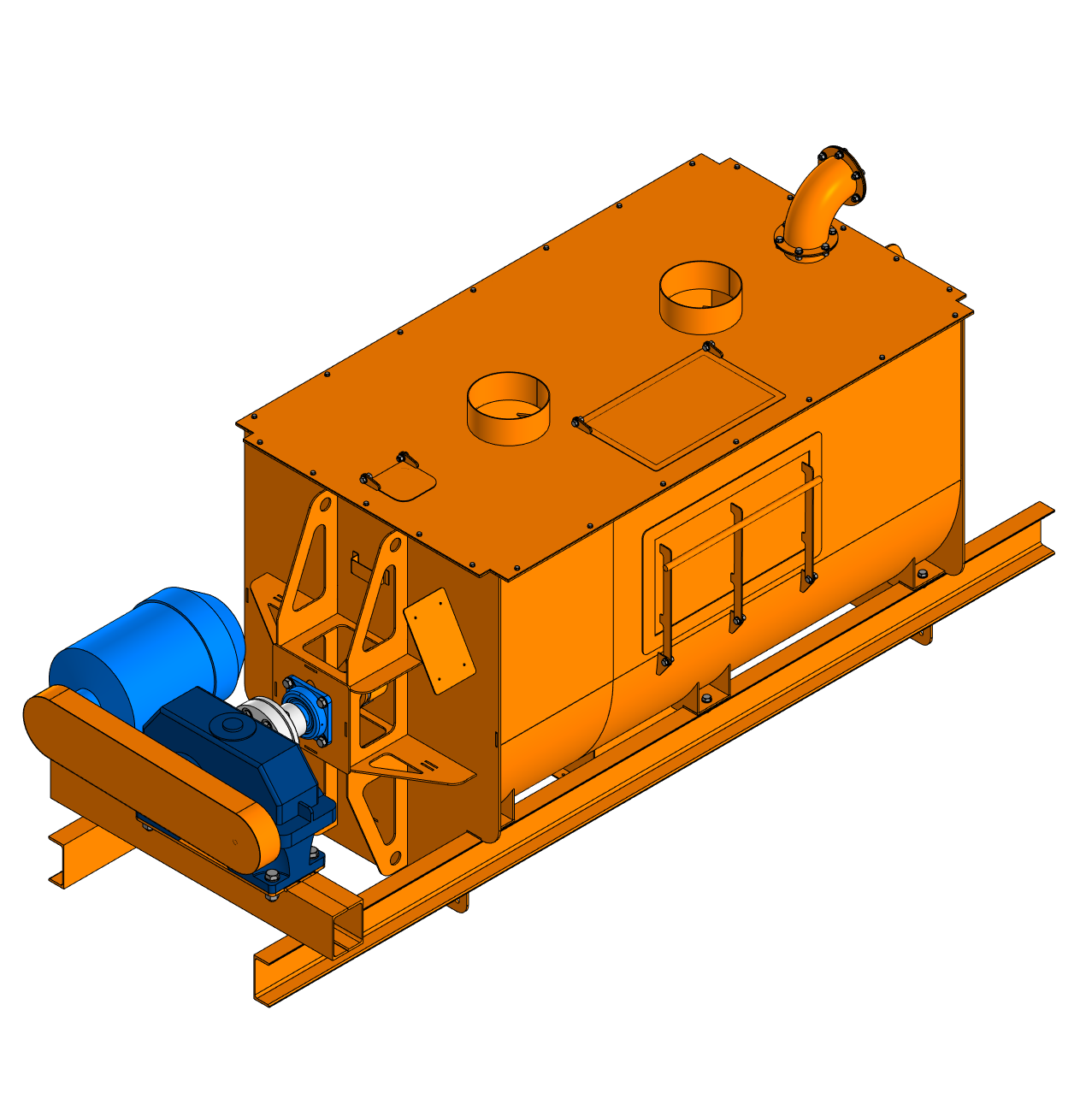

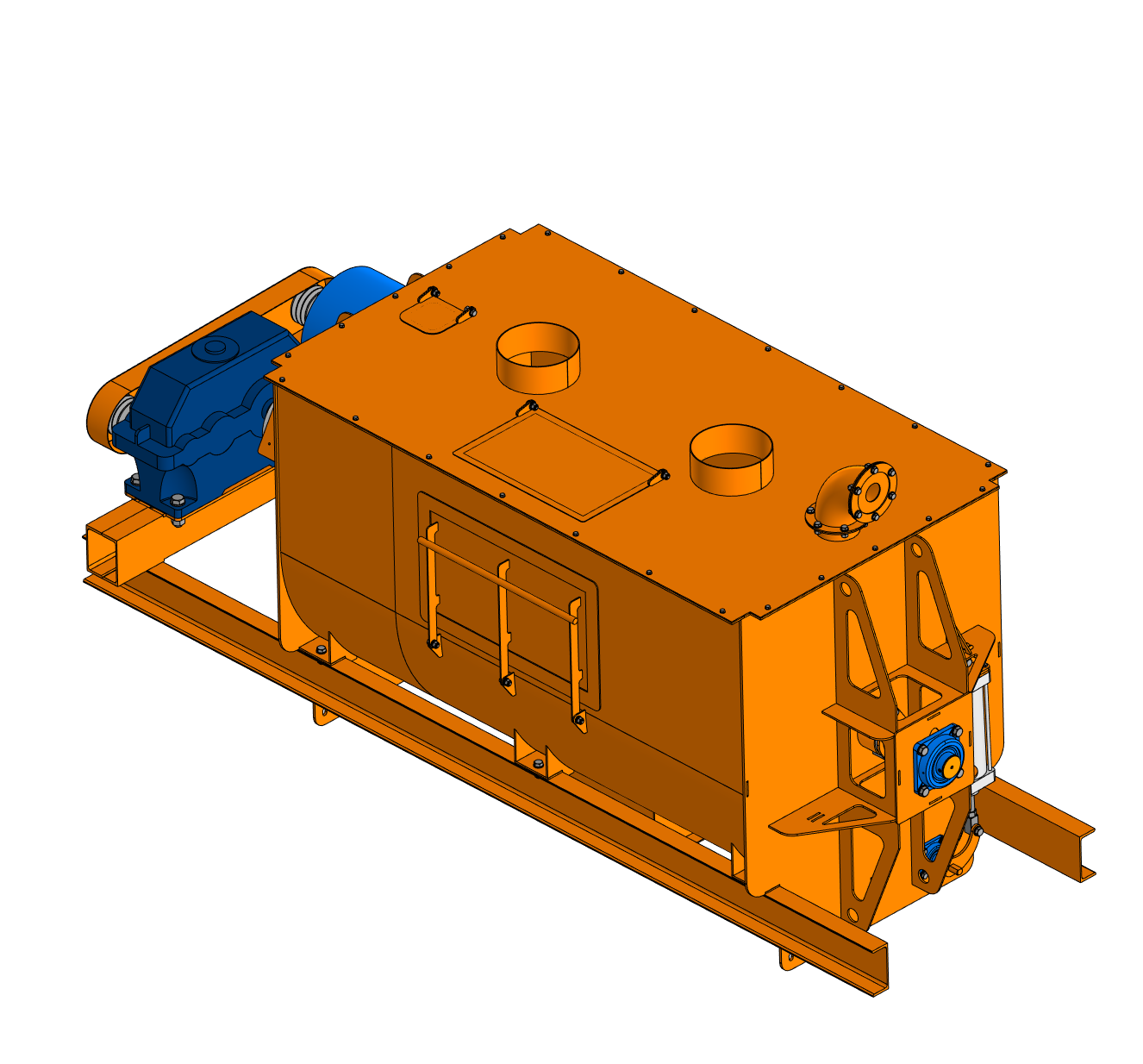

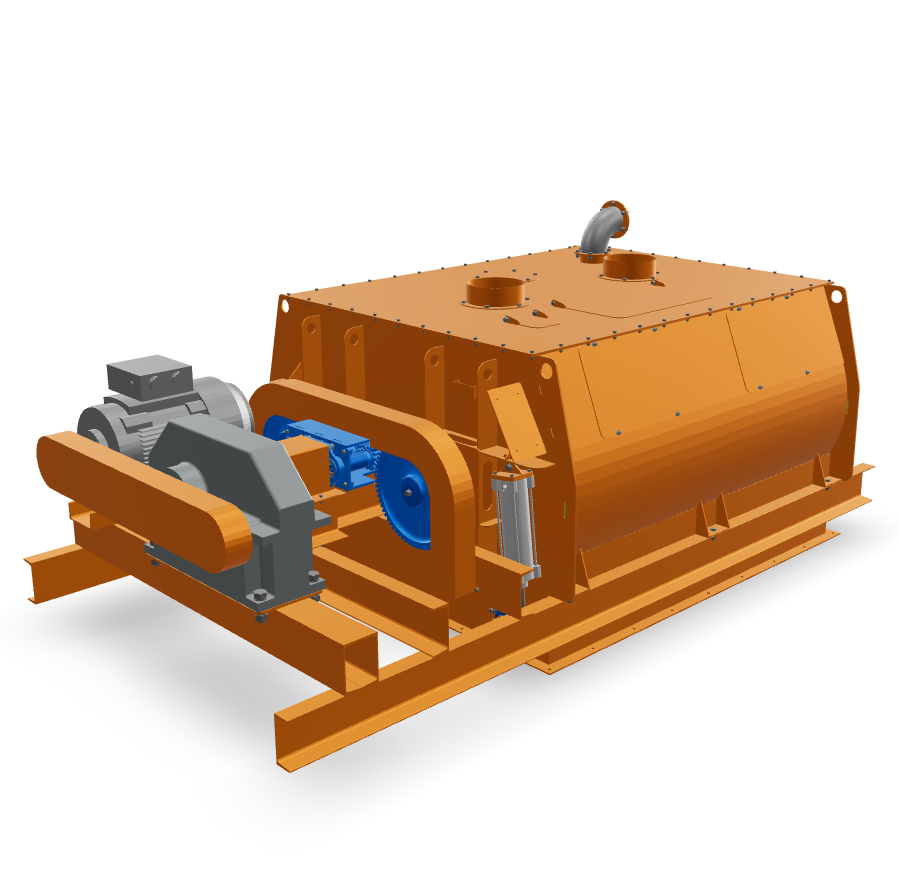

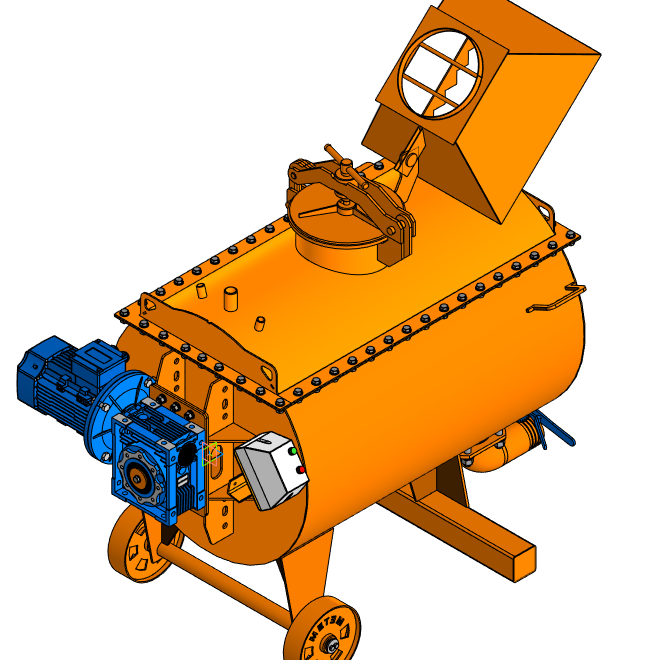

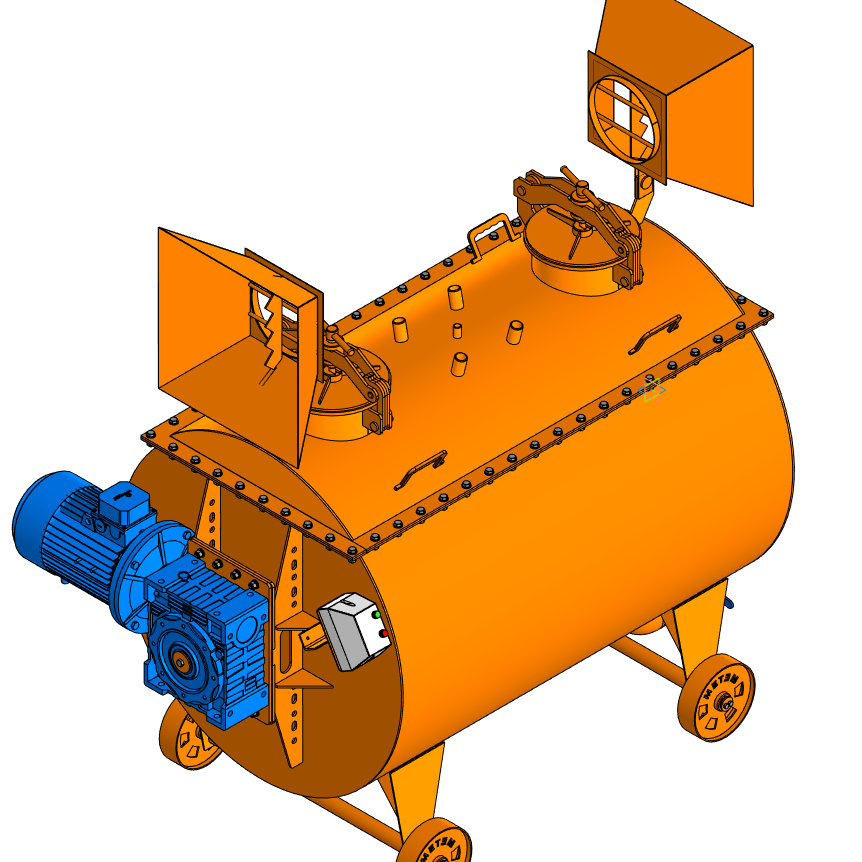

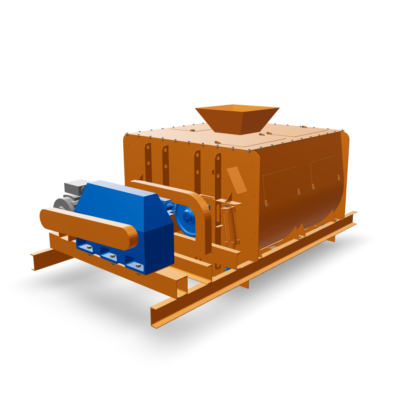

Mixer for dry mixes CC-1500

with delivery across Russia

Mixer for dry mixes CC-1500

with delivery across Russia

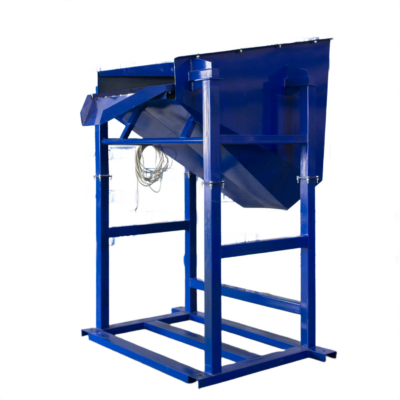

The dry mix mixer "SS-1500" is designed for mixing bulk materials such as: sand, cement, gypsum, chalk, bentonite, thermoplastic, etc.

Available on back-order

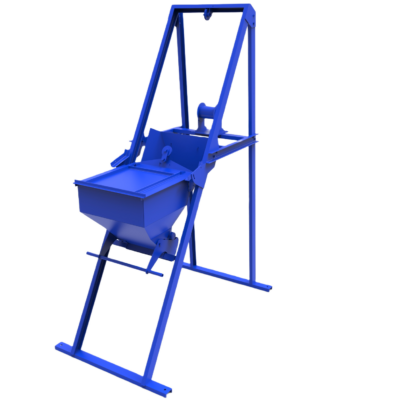

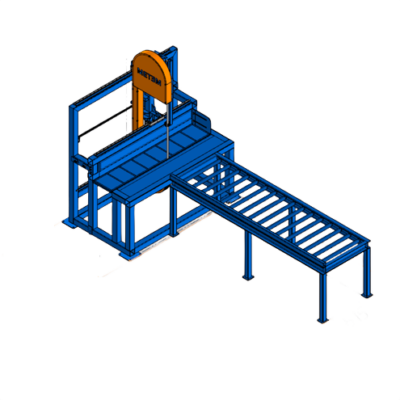

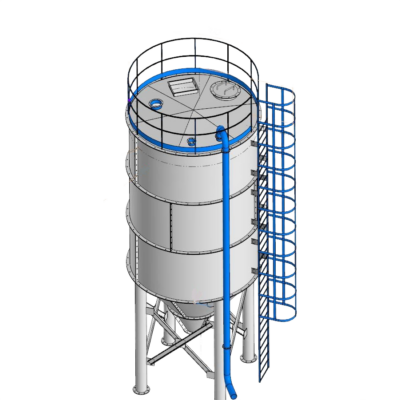

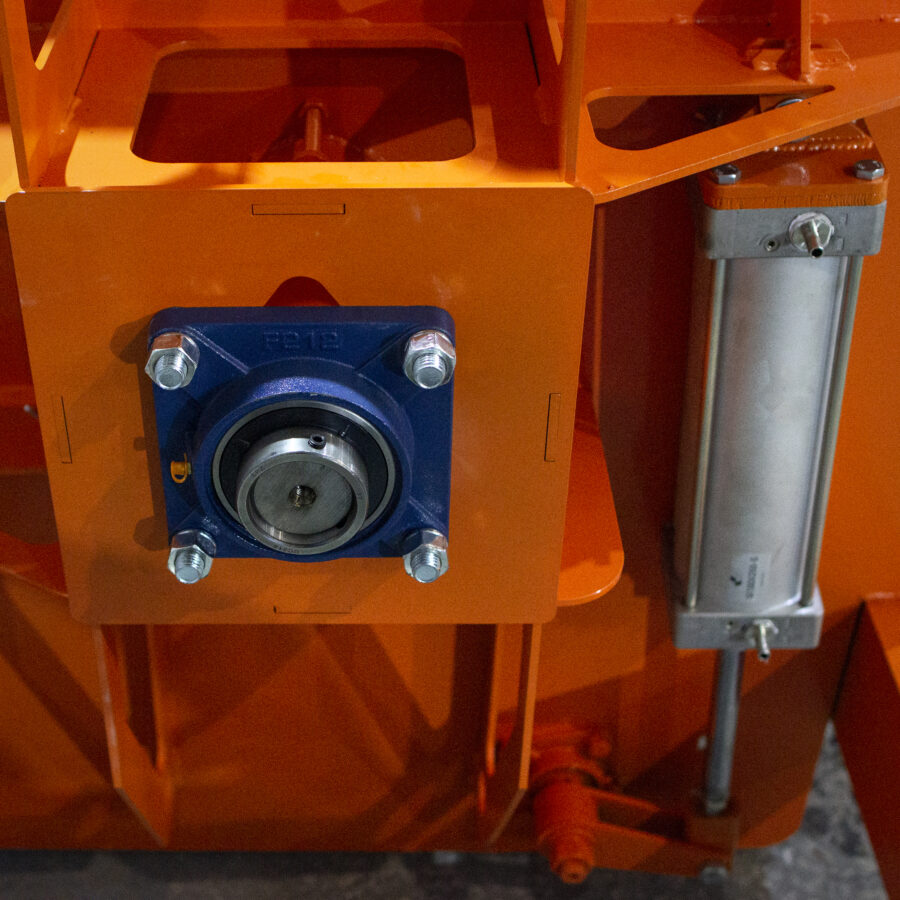

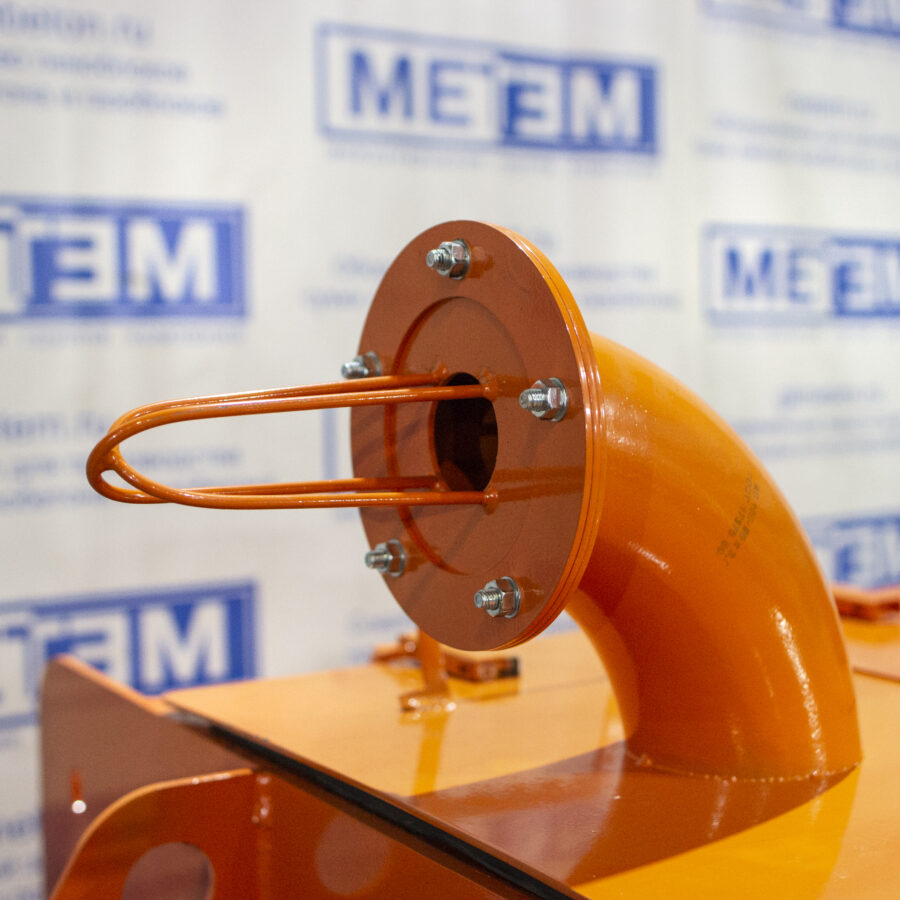

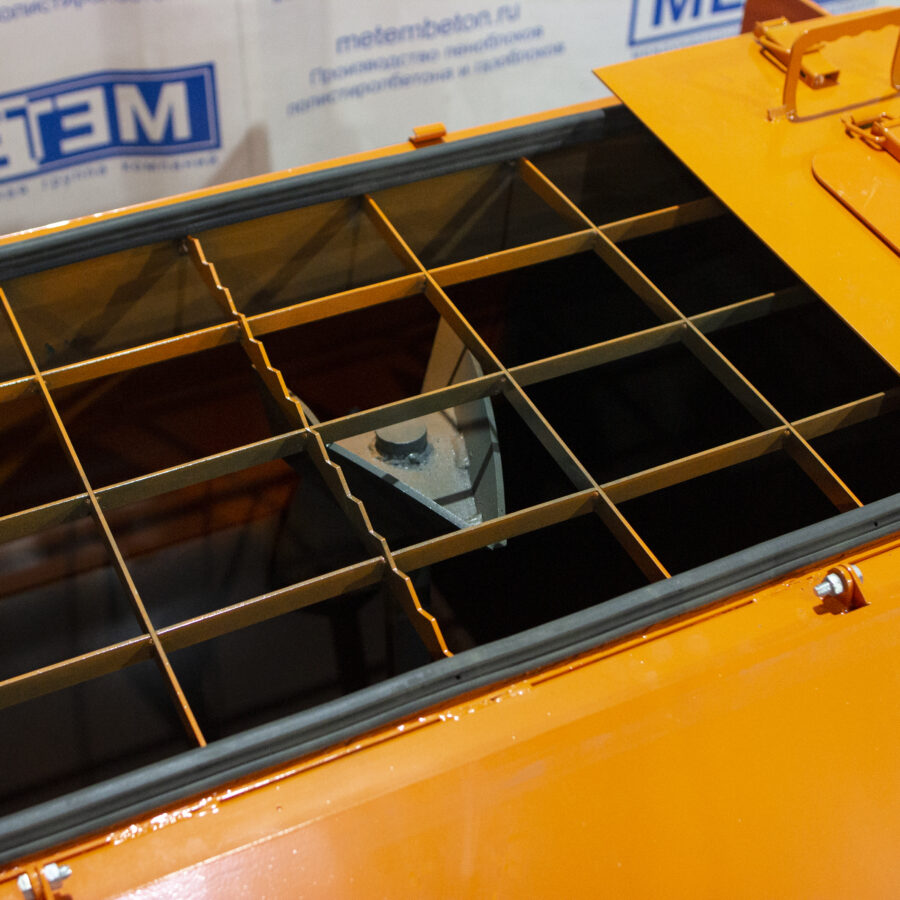

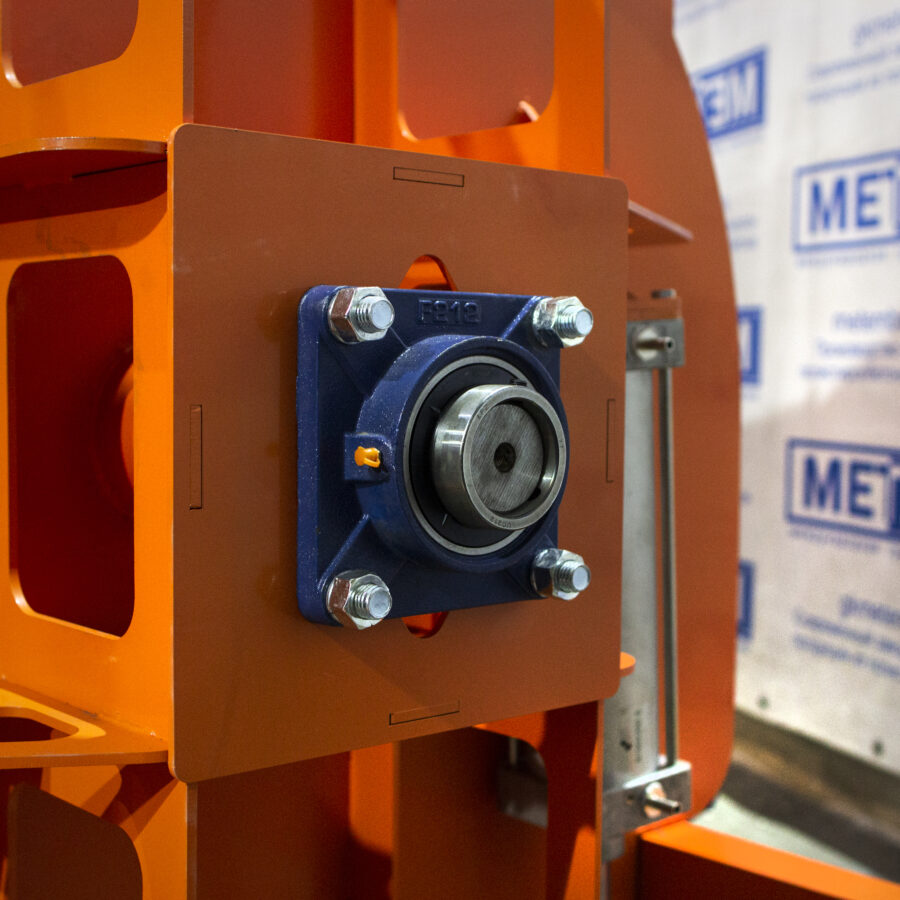

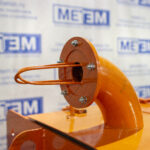

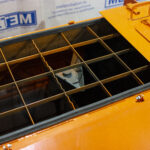

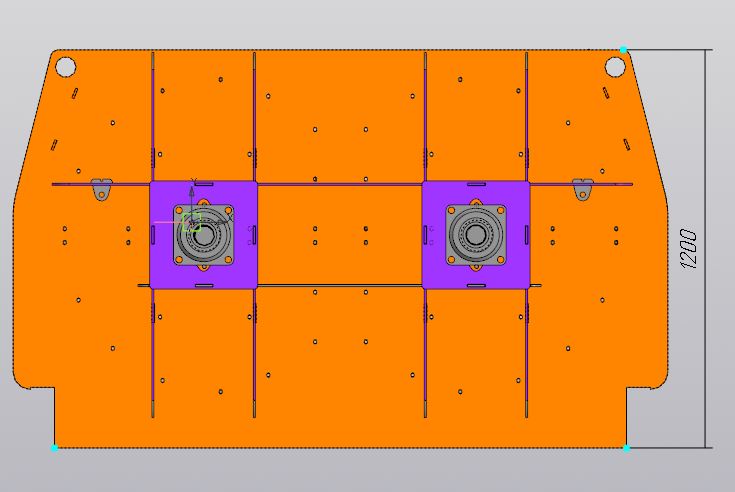

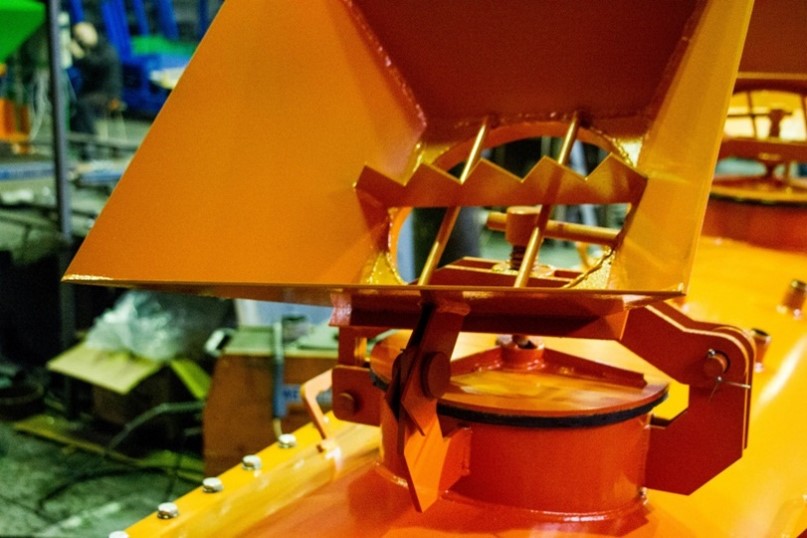

The dry mix mixer "SS-1500" is designed to mix bulk materials such as: sand, cement, gypsum, chalk, bentonite, thermoplastic, etc. The mixer is equipped with an all-metal shaft and reinforced plow blades (it is possible to install other mixing elements upon request) for fast and high-quality mixing of components. In the lower part, there is an unloading hatch with a pneumatic drive for easy unloading of the finished mixture. The hatch is rounded to match the bottom radius, which eliminates the non-mixing zone. The mixer shell is made of 6 mm thick steel, the side walls are 8 mm (if necessary, it is equipped with armor). A large inspection hatch is installed on the "SS-1500" shell for easy maintenance, and a small hatch on top for adding additives. The 15 kW drive is equipped with a cylindrical reducer and a belt drive, which simplifies maintenance, reduces the noise level at the production site and increases the service life of the mixer. The upper part is manufactured in agreement with the Customer. Options for manual loading or for any type of conveyors or dispensers are possible.

| Weight | 1350 kg |

|---|---|

| Dimensions | 3100×1600×1600 mm |

| Mixer volume |

1500 ,l |

| Shaft rotation frequency |

50 ,rpm |

| Performance |

10-12 ,t/hour |

| Filler fraction |

no more than 50 ,mm. |

| Power supply voltage |

380 ,IN |

| Mixer motor power |

15 ,kW |

| Size of the unloading hatch |

340*275 ,mm. |

| Volume of finished mixture |

up to 1200 ,l. |

| Nominal air pressure |

8 ,atm. |

No video